| Availability: | |

|---|---|

KINDLE

Plywood log grabber

A log grabber is a multifunctional machine that uses a hydraulically driven rotating gripper to grab, transfer, stack, and load and unload timber. Its core function is to replace manual labor, solving the challenge of handling heavy, bulky timber, significantly improving logistics efficiency and reducing safety risks. Advantages include: efficient adaptation to irregular materials such as logs and lumber; strong gripping force and flexible rotation capabilities for complex applications; and significant reductions in labor costs and the risk of workplace injuries.

Machine parameter

| Engine type | 490 | Rated power | 36.8kw |

| Rated speed | 2400r/min | Number of cylinders | four |

| brand | yuneni(or quanchai、xichai) | gearbox | 265Hydraulic torque converter |

| Gear position | 4F4R | Drive axle | Small wheel reduction bridge |

| Braking mode | Clamp disc air brake | Tyre type | 20.5/70-16 |

| Machine weight | 3830kg | Rated load | 1000kg |

| Bucket width | 1800mm | Dipper capacity | 1.4m³ |

| Arm thickness | 25mm | Unloading height | 4200mm |

| unloading distance | 1400mm | Ternary sum | 12s |

| Wheel track | 1500mm | wheelbase | 2300mm |

| Maximum steering Angle | ±30° | Climbing ability | 30% |

| Maximum speed | 30km/h | Fuel tank | 50L |

| Hydraulic tank | 50L | Minimum ground clearance | 240mm |

| Machine size (l* w * h) | 6400*1800*2750mm | Total height (mm) | 1600mm |

| Number of teeth | 3+4 | Maximum opening size (mm) | 1400mm |

| Grip width (mm) | 1050*740mm | Minimum closing size (mm) | 300mm |

| Grip length (mm) | 1000mm |

1. Efficient and Flexible Operation

The hydraulic gripper supports 360° rotation and multi-angle opening and closing, enabling rapid grasping, flipping, and stacking of logs of various shapes. It adapts to narrow spaces and complex stacking requirements, significantly improving handling efficiency.

2. Powerful and Durable

The heavy-duty engine and reinforced structural design provide tremendous gripping force and impact resistance, enabling continuous handling of high-intensity logs with a long service life.

3. Safe and Economical

Mechanical operation reduces manual intervention, minimizing the risk of injury and collision during log handling. Furthermore, the single-machine operation can replace the collaborative efforts of multiple personnel, significantly saving labor costs.

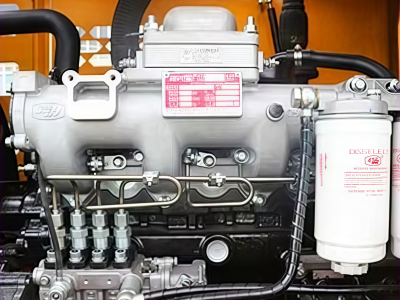

QUALITY ENGINE

Equipped with a high-horsepower brand-name diesel engine, this machine delivers robust power output and massive torque for demanding workloads, while advanced fuel injection technology ensures exceptional fuel economy and lower operating costs.

WEAR-RESISTANT TOOTHED TIRES

The slots feature a non-slip and wear-resistant design, ensuring reliable grip and long-term durability. Combined with thickened high-quality tire walls, this construction significantly enhances puncture resistance and stability, thereby greatly improving operational safety in various working conditions.

HYDRAULIC HOSE

High-strength hydraulic tubing ensures smooth and powerful system operation and stable and reliable power output. Precision-processed sealing eliminates the risk of oil leakage and ensures long-term clean operation. High-quality materials and exquisite craftsmanship are clearly visible, and superior quality is reflected in every detail.

WEIGHTED AXLE

The high-quality axle assembly, precision-manufactured from high-strength materials, offers exceptional structural strength and impact resistance, resisting deformation even under extreme operating conditions. Its high ground clearance enhances maneuverability over complex terrain, while an optimized transmission structure significantly reduces operating noise.

COMFORT CAB

The workbench features an intuitive and accessible layout, minimizing unnecessary movements and reducing operational errors. Paired with an ergonomically designed anti-fatigue seat that provides optimal lumbar support, this combination significantly enhances operator comfort during extended shifts, reduces physical fatigue, and maintains sustained productivity.

FREE ROTATION

The high-strength slewing bearing device is equipped with a precise speed control system, which can realize 360-degree free rotation in clockwise and counterclockwise directions. This design ensures the stability and rotation accuracy of the equipment under heavy load conditions, greatly improves the operation flexibility and efficiency, and enhances the adaptability and reliability of the equipment under complex working conditions.

Our plywood log grabber and plywood machine are exported to many countries like Malaysia,Indonesia, Russia, Turkey ,Brazil, Argentina, Paraguay and so on.

Spindleless peeler

Card peeling machine

Veneer dryer

Hot press

Cold press

Plywood trimming saw

Automatic putty line

Glue spreader

Company Profile

Shandong kindle Machinery manufacture limited company located in Linyi national Economic and Technological Development Zone, it was founded in 1998 which specialized in research and development of veneer peeling machine for 26 years. It have obtained more than 60 national patents , it covers more than 30000 area and have 15 R&D technician and 30 professional engineer for installation and machine maintaining.

We are committed to provide complete solutions for veneer

peeling line, plywood making plant,LVL,block board, PB,OSB production Line etc. Main equipment include: Log cutting saw, log debarker , spindle peeling lathe and spindleless wood veneer peeling machine,veneer dryer, glue spreader,pre-press, hot press, veneer commposer,plywood saw, sanding machine, boiler, and related plant accessories and materials, etc.

FAQ:

Q1: Are you machine manufacturer or a trading company?

A1: We are a factory which is special for producing veneer peeling machine and plywood machine,Jinduo company own 2 workshops and 1 trading company.

Q2: What is the delivery time?

A2: In generally speaking , the complete veneer product line need about 30 days to manufacture after getting deposit.

Q3: What is the maintenance period and what kind of after sale service can you supply?

A3: The machinery part maintenance will be sustained in one year after installation and we have abroad warehouse and office for spare part in brazil and Russia, our engineer will arrive your factory to maintain the machine at first time if have problem.

Q4: What is the payment term?

A4: We can accept TT with 30% deposit and 70% balance against loading bill or 100% irrevocable L/C at sight.

Q5: Can we visit your factory?

A6: Jinduo company is next to linyi airport, we can pick you up from airport to our factory at any time, welcome to visit us.