| Availability: | |

|---|---|

KINDLE

The roller table for plywood production offers four key advantages: efficient conveying, surface protection, adjustable speed, and robust durability. It significantly enhances productivity through automated smooth transportation while reducing manual handling. Its smooth-rolling design prevents surface scratches to ensure product quality. With variable frequency speed control, it adapts to different plywood thicknesses and sizes. The high-quality steel construction ensures stable performance during prolonged heavy-duty operations, substantially lowering maintenance costs.

Machine parameter

| 1.5 ton | 2.0 ton | 2.5 ton |

| 3000 | 3000 | 3000 |

| 2 stage 3 meters mast | 2 stage 3 meters mast | 2 stage 3 meters mast |

| 95 | 95 | 95 |

| 6 °/12 ° | 6 °/12 ° | 6 °/12 ° |

| 12#Guobiao C type steel | 12#Guobiao steel | 12#Guobiao steel |

| 15/13 | 15/13 | 15/13 |

| 2330*1200*2150 | 2430*1200*2150 | 2550*1200*2150 |

| Special aluminum shell integrated axle | Cast steel integrated square axle | Cast steel integrated axle |

| 650-10 | 650-10 | 650-10 |

| 500-8 | 500-8 | 500-8 |

| 1580 | 1650 | 1790 |

| 1030 | 1020 | 1020 |

| 870 | 950 | 920 |

| steel plate axle | steel plate axle | steel plate axle |

| oil brake | oil brake | oil brake |

| 3.0(chongqingkecheng) | 5.0(chongqingkecheng) | 5.0(chongqingkecheng) |

| 3.0(chongqingkecheng) | 4.0(chongqingkecheng) | 5.0(chongqingkecheng) |

| 60 | 60 | 60 |

| 70(Five chaowei maintenance-free) | 70(Ten chaowei maintenance-free) | 70(Ten chaowei maintenance-free) |

| 2150 | 2600 | 3200 |

| Seat power off Code to get on | Seat power off Code to get on | Seat power off Code to get on |

1.Powered by electricity with no exhaust pollution, aligning with global low-carbon initiatives.

2.Energy consumption costs are only 1/3 of fuel forklifts, with 50%+ lower maintenance expenses.

3.Equipped with intelligent speed control for rapid response and quiet performance, ideal for indoor/outdoor precision tasks.

4. Lithium batteries enable 4-8 hour quick charging with 10-12 hours of continuous operation.

High Efficiency & Energy Savings

Equipped with high-density lithium batteries for fast charging, long lifespan, and 30%+ longer endurance, supported by energy recovery technology.

INTELLIGENT

intelligent intelligent control system for responsive operation and multiple working modes to adapt to varying load demands.

Eco-Friendly

Zero exhaust emissions, reducing carbon footprint and complying with global environmental standards.

Our forklifts are recognized by the market in Brazil/Russia/Malaysia/Indonesia/Argentina and other countries.

Spindleless peeler

Veneer dryer

Veneer composer

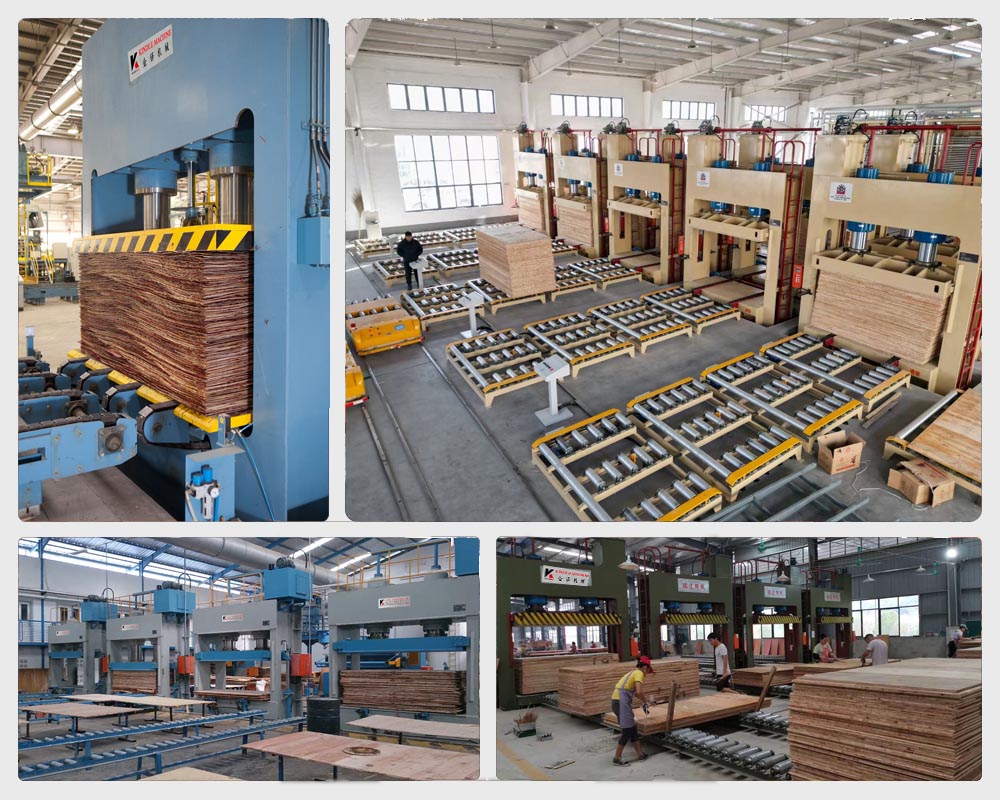

Hot press

Glue spreader

plywood trimming saw

Automatic putty line

Calibrating machine

Shandong kindle Machinery manufacture limited company

located in Linyi national Economic and Technological Deve-

lopment Zone, it was founded in 1998 which specialized in

research and development of veneer peeling machine for 26

years. It have obtained more than 60 national patents , it covers more than 30000 area and have 15 R&D technician and 30 professional engineer for installation and machine maintaining.

![]()

We are committed to provide complete solutions for veneer

peeling line, plywood making plant,LVL,block board, PB,OSB production Line etc. Main equipment include: Log cutting saw, log debarker , spindle peeling lathe and spindleless wood veneer peeling machine,veneer dryer, glue spreader,pre-press, hot press, veneer commposer,plywood saw, sanding machine, boiler, and related plant accessories and materials, etc.

![]()

FAQ:

Q1:Are you machine manufacturer or a trading company?

A1: we are a factory which is special for producing veneer peeling machine and plywood machine,Jinduo company own 2 workshops and 1 trading company

Q2:What is the delivery time?

A2:In generally speaking , the complete veneer product line need about 30 days to manufacture after getting deposit.

Q3: what is the maintenance period and what kind of after sale service can you supply?

A3: the machinery part maintenance will be sustained in one year after installation and we have abroad warehouse and office for spare part in brazil and Russia, our engineer will arrive your factory to maintain the machine at first time if have problem.

Q4: what is the payment term?

A4: we can accept TT with 30% deposit and 70% balance against loading bill or 100% irrevocable L/C at sight.

Q5:can we visit your factory?

A6: Jinduo company is next to linyi airport, we can pick you up from airport to our factory at any time, welcome to visit us.