| Availability: | |

|---|---|

KINDLE

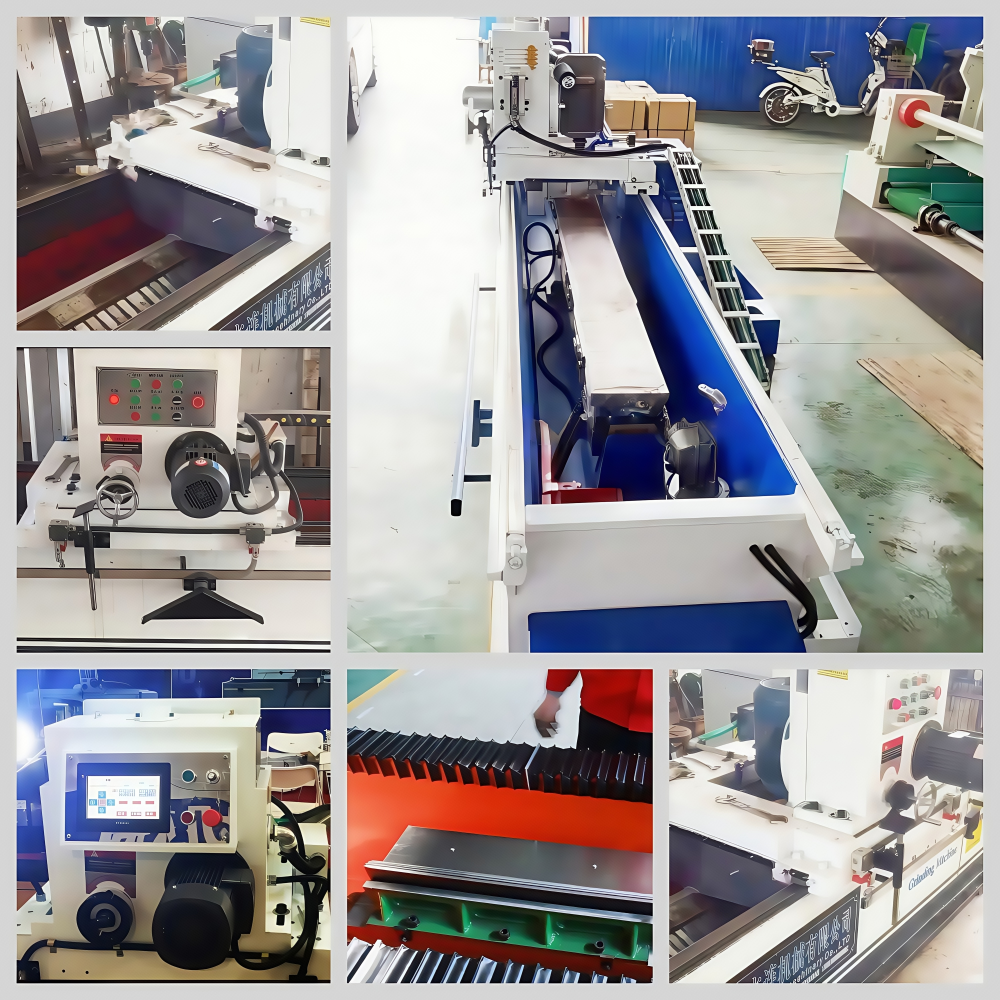

Plywood knife sharpener machine

The plywood sharpening machine quickly restores the sharpness of the tool through high-precision automated grinding, significantly improving the smoothness and thickness uniformity of plywood cutting. At the same time, it extends the tool life, reduces downtime, effectively reduces production costs and ensures production safety.

Machine parameter

| Model | HMD1500C | HMD3000C |

| Grinding wheel | White fused alumina | Resin/White fused alumina |

| Max.Grinding length | 1500mm | 3000mm |

| Work table width | 180mm | 180mm |

| Work table angle range | ±45° | ±45° |

| Grinding head motor power | 4kw | 4kw |

| Grinder line speed | 15.5m/s | 15.5m/s |

| Plate moving speed | 17m/min | 17m/min |

| Overall dimension | 3540*1600*1400mm | 5040*1600*1400mm |

| Weight | 2000kg | 2750kg |

1. High Precision: Capable of producing gears of the highest precision, significantly improving transmission smoothness.

2. High Surface Quality: Grinding produces an exceptionally smooth surface finish, reducing wear and operating noise.

3. High Hardness Processing: Capable of finishing high-hardness gears after quenching or other heat treatments, and correcting deformation.

High-Quality Wheels

The wheel's high-precision dynamic balancing design and wear-resistant material ensure the straightness and sharpness of the tool edge, significantly improving the surface cutting quality of plywood. Its long-lasting durability reduces maintenance costs and downtime, and it is easy to operate and highly reliable.

Convenient Operation Panel

The knife sharpener's operation panel integrates intelligence, integration, and security. Through touchscreen digital interaction, one-touch process presets, and seal permission management, it significantly improves operational accuracy, efficiency, and safety, while reducing manual reliance.

Alarm system

The knife sharpener's warning system uses multi-level sound and light alarms and intelligent diagnostic functions to monitor equipment status in real time (such as motor overload, grinding wheel wear, and coolant abnormalities), accurately locate faults, and suggest solutions, effectively preventing operational risks and equipment damage, and ensuring production safety and continuity.

Our plywood knife sharpener machine and plywood machine are exported to many countries like Malaysia,Indonesia, Russia, Turkey ,Brazil, Argentina, Paraguay and so on.

Spindleless peeler

Card peeling machine

Veneer dryer

Hot press

Cold press

Plywood trimming saw

Automatic putty line

Glue spreader

Company Profile

Shandong kindle Machinery manufacture limited company located in Linyi national Economic and Technological Development Zone, it was founded in 1998 which specialized in research and development of veneer peeling machine for 26 years. It have obtained more than 60 national patents , it covers more than 30000 area and have 15 R&D technician and 30 professional engineer for installation and machine maintaining.

We are committed to provide complete solutions for veneer

peeling line, plywood making plant,LVL,block board, PB,OSB production Line etc. Main equipment include: Log cutting saw, log debarker , spindle peeling lathe and spindleless wood veneer peeling machine,veneer dryer, glue spreader,pre-press, hot press, veneer commposer,plywood saw, sanding machine, boiler, and related plant accessories and materials, etc.

FAQ:

Q1: Are you machine manufacturer or a trading company?

A1: We are a factory which is special for producing veneer peeling machine and plywood machine,Jinduo company own 2 workshops and 1 trading company.

Q2: What is the delivery time?

A2: In generally speaking , the complete veneer product line need about 30 days to manufacture after getting deposit.

Q3: What is the maintenance period and what kind of after sale service can you supply?

A3: The machinery part maintenance will be sustained in one year after installation and we have abroad warehouse and office for spare part in brazil and Russia, our engineer will arrive your factory to maintain the machine at first time if have problem.

Q4: What is the payment term?

A4: We can accept TT with 30% deposit and 70% balance against loading bill or 100% irrevocable L/C at sight.

Q5: Can we visit your factory?

A6: Jinduo company is next to linyi airport, we can pick you up from airport to our factory at any time, welcome to visit us.