| Availability: | |

|---|---|

KINDLE

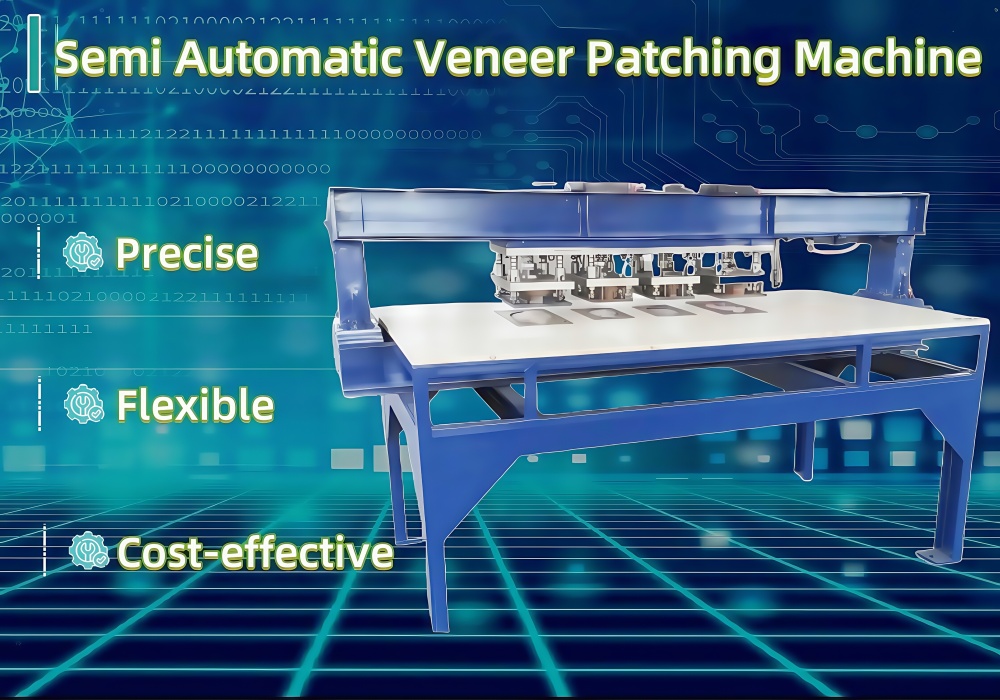

Semi Automatic Veneer Patching Machine

The plywood semi-automatic patching machine is a highly efficient device designed to repair surface defects (such as cracks, knots, and insect holes) on veneer boards. It achieves precise defect repair by combining manual positioning with mechanical automated repair. Compared to fully automatic patching machines, semi-automatic models offer significant advantages in cost, flexibility, and precision: they are lower priced, easier to maintain, and are particularly suitable for small and medium-sized manufacturers. The manual intervention allows them to flexibly handle special-shaped veneers, such as curved surfaces or irregular edges.

Machine parameter

| Model | Unit | HWB3848 | ||

| Mending speed | sec/time | 3-5 | ||

| Veneer Thickness | mm | 0.8-3.0 or 2.0-8.0mm optional | ||

| Diameter of cylinder | mm | 50 | ||

| N.W. | kg | 1500 | ||

1. Economical and Efficient: The equipment boasts low purchase costs (only one-third of fully automatic models), energy and maintenance costs are reduced by over 40%, and the payback period is short, making it particularly suitable for small and medium-sized manufacturers.

2. Human-Machine Collaboration: While retaining manual quality inspection and positioning, operators can determine defect characteristics (such as grain direction and color difference) in real time, leveraging the dual-insurance of "AI vision + empirical judgment" to increase repair accuracy to 98%.

3. Flexible Adaptability: With an adjustable clamp and manual fine-tuning mechanism, the system can handle both conventional single-board panels (0.3-5mm thick) and curved and shaped panels (such as musical instrument panels). Changing the patch material (veneer/resin) takes only 30 seconds.

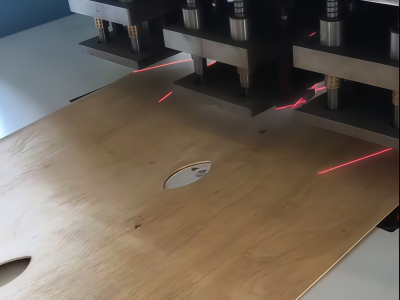

Infrared Inspection System

This semi-automatic panel repair machine's infrared inspection system uses advanced thermal imaging technology to accurately identify various surface and internal defects on the panels, including subtle cracks and hollows that are difficult to detect with the naked eye.

Seamless quick cutting

The plywood semi-automatic patching machine uses a high-precision cutting system to quickly and accurately complete the patching operation, with smooth cuts and no burrs. It is equipped with a special ultra-thin blade and intelligent pressure adjustment function, which can automatically adapt to veneers of different thicknesses and materials, ensuring that there is no fiber tearing or edge collapse during the cutting process.

Diverse Shapes

The plywood semi-automatic patching machine offers exceptionally versatile cutting capabilities, enabling precise repair of defects in a wide range of complex shapes. Its intelligent profiling system automatically identifies irregular contours of defects, such as wormholes and cracks, and generates a matching cutting path.

Our semi-automatic veener patching machine and plywood machine are exported to many countries like Malaysia,Indonesia, Russia, Turkey ,Brazil, Argentina, Paraguay and so on.

Spindleless peeler

Card peeling machine

Veneer dryer

Hot press

Cold press

Plywood trimming saw

Automatic putty line

Glue spreader

Company Profile

Shandong kindle Machinery manufacture limited company located in Linyi national Economic and Technological Development Zone, it was founded in 1998 which specialized in research and development of veneer peeling machine for 26 years. It have obtained more than 60 national patents , it covers more than 30000 area and have 15 R&D technician and 30 professional engineer for installation and machine maintaining.

We are committed to provide complete solutions for veneer

peeling line, plywood making plant,LVL,block board, PB,OSB production Line etc. Main equipment include: Log cutting saw, log debarker , spindle peeling lathe and spindleless wood veneer peeling machine,veneer dryer, glue spreader,pre-press, hot press, veneer commposer,plywood saw, sanding machine, boiler, and related plant accessories and materials, etc.

FAQ:

Q1: Are you machine manufacturer or a trading company?

A1: We are a factory which is special for producing veneer peeling machine and plywood machine,Jinduo company own 2 workshops and 1 trading company.

Q2: What is the delivery time?

A2: In generally speaking , the complete veneer product line need about 30 days to manufacture after getting deposit.

Q3: What is the maintenance period and what kind of after sale service can you supply?

A3: The machinery part maintenance will be sustained in one year after installation and we have abroad warehouse and office for spare part in brazil and Russia, our engineer will arrive your factory to maintain the machine at first time if have problem.

Q4: What is the payment term?

A4: We can accept TT with 30% deposit and 70% balance against loading bill or 100% irrevocable L/C at sight.

Q5: Can we visit your factory?

A6: Jinduo company is next to linyi airport, we can pick you up from airport to our factory at any time, welcome to visit us.