| Feeding width: | |

|---|---|

| layers: | |

| hot press: | |

| product capacity: | |

| Availability: | |

JDHG48-15L

KINDLE

Veneer dryer machine is mainly used to dry the core veneer to solve high moisture content problem after peeling.

The machine can dry veneers of various thickness and moisture contents. Any wood spices can be dried in this machine.This Hot press type veneer dryer is very popular among small factories, which can not only press the veneer,but also dry it.After dried by this machine, it can improve quality of the final products, so it is a smart choice for plywood manufacturers.

Machine parameter

| Model | JDHG280Y-15L | JDHG280Y-12L |

| Normal pressure | 60Tons | 60Tons |

| Platen Material | Q235 with small groove 1.5mm depth | Q235 with small groove 1.5mm depth |

| Size of Hot platen | 2800*1370* 42mm 2 in 2 out with groove | 2800*1370* 42mm 2 in 2 out with groove |

| Oil Cylinders | ø100*1050mm*4pcs | ø100*1050mm*4pcs |

| Total power | 15 KW | 15 KW |

| Layers | 15 openings | 12 openings |

| Spacing of layer | 70mm | 70mm |

| Hot platen | 16 pcs | 16 pcs |

| Colum width | 350 mm | 350 mm |

| Walking beam | 300mm | 300mm |

| Closing time | About 15S | About 12S |

| Total weight | 28000kgs | 23500kgs |

| Overall dimension | 3550*1370*3300mm | 3550*1370*3300mm |

1.The machine equipped with symmetrically level spring synchronous closing mechanism,the pressing plates and core can connect and disconnect at the same time.

2.Hot plates after a special crafted, with a fast moister remove and exhaust functions.

3.Rack uses framework of institutions, up inlet hydro-cylinder, easy installation and less infrastructure investment.

4.Estimated drying capacity is 20cbm/24hours(4*8ft,1.5mm thickness veneer,moisture 70% - 10%)

THE PRESS PLATEN

Grooved hot press platen, special for core veneer dryer use, easy to breath out moisture when drying.make the drying effect better.hot plate has a favorable tide exhaust groove on both sides, which makes veneer exhaust moisture fast and efficiently.

STEAMLESS TUBE PLATE

Its hot plate is produced by the seamless steel pipe. Good performance for air-tightness.It is suitable for drying the core veneer to solve high moisture content problemafter peeling. Low cost, low investment, installed dimension is small.

The working layers quantity can be designed according to client's requirement.

SOLID FRAME

Heavy duty and welded steel frame, international standard hydraulic system and electrical components, long time using.

BEST CHOICE FOR SMALL FACTORY

No foundation is required for this machine,best choice for small or new factory.The machine equipped with symmetrically level spring synchronous closing mechanism,the pressing plates and core can connect and disconnect at the same time.

Our veneer dryer machine and plywood machine are exported to many countries like Malaysia,Indonesia, Russia, Turkey ,Brazil, Argentina, Paraguay and so on.

Spindleless peeler

Veneer dryer

Veneer composer

Hot press

Glue spreader

plywood trimming saw

Automatic putty line

Calibrating machine

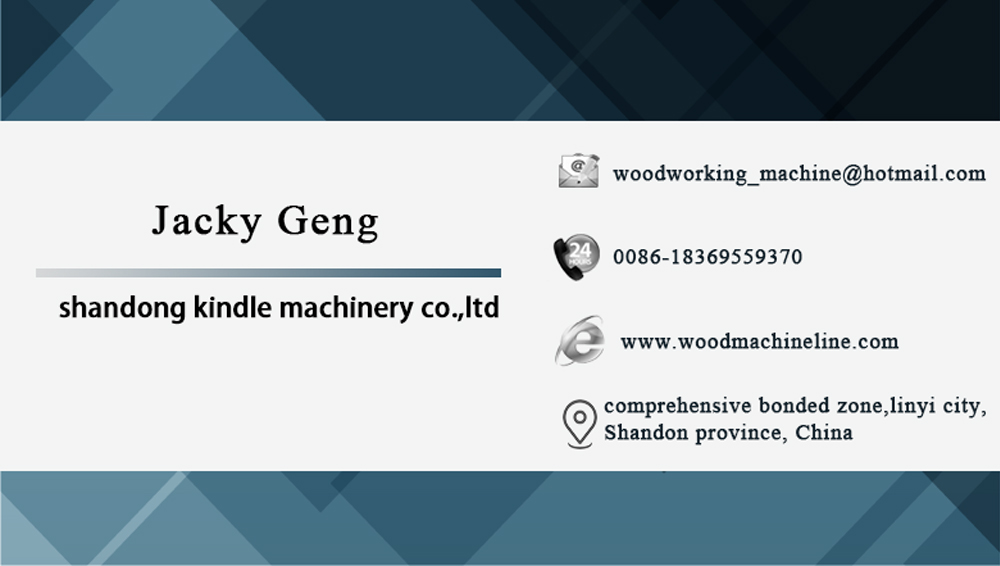

Shandong kindle Machinery manufacture limited company

located in Linyi national Economic and Technological Deve-

lopment Zone, it was founded in 1998 which specialized in

research and development of veneer peeling machine for 26

years. It have obtained more than 60 national patents , it covers more than 30000㎡ area and have 15 R&D technician and 30 professional engineer for installation and machine maintaining.

![]()

We are committed to provide complete solutions for veneer

peeling line, plywood making plant,LVL,block board, PB,OSB production Line etc. Main equipment include: Log cutting saw, log debarker , spindle peeling lathe and spindleless wood veneer peeling machine,veneer dryer, glue spreader,pre-press, hot press, veneer commposer,plywood saw, sanding machine, boiler, and related plant accessories and materials, etc.

![]()

FAQ:

Q1:Are you machine manufacturer or a trading company?

A1: we are a factory which is special for producing veneer peeling machine and plywood machine,Jinduo company own 2 workshops and 1 trading company

Q2:What is the delivery time?

A2:In generally speaking , the complete veneer product line need about 30 days to manufacture after getting deposit.

Q3: what is the maintenance period and what kind of after sale service can you supply?

A3: the machinery part maintenance will be sustained in one year after installation and we have abroad warehouse and office for spare part in brazil and Russia, our engineer will arrive your factory to maintain the machine at first time if have problem.

Q4: what is the payment term?

A4: we can accept TT with 30% deposit and 70% balance against loading bill or 100% irrevocable L/C at sight.

Q5:can we visit your factory?

A6: Jinduo company is next to linyi airport, we can pick you up from airport to our factory at any time, welcome to visit us.