| Feeding width: | |

|---|---|

| layers: | |

| conveyor type: | |

| product capacity: | |

| Availability: | |

JDHG3000-4L

KINDLE

The veneer dryer is main machine for plywood production,it's used for fresh veneer drying.It includes mesh belt dryer,roller dryer and mesh & roller medley dryer,can be customized according to your requirements.

This veneer dryer industrial equipment helps you to efficiently process plywood veneer wood with the advantages of improved fan and thermal circulation system, fully automatic entry and exit plank device, widened working band, newly designed new modeling spray box, intelligent humidity control system and hot air leakage recovery device. it improves the product capacity of veneer drying uncommonly.

Machine parameter

| Model | JDHG320R-4L | JDHG470R-4L |

| Veneer thickness | 1.0-4.0mm | 1.0-4.0mm |

| Feeding width | 3200mm | 4700mm |

| Layer | 4 | 4 |

| Heating area length | 30m(15chamber * 2m) | 22m(11chamber * 2m) |

| Cooling area length | 4m | 4m |

| Initial moisture content | <70% | <70% |

| Final moisture content | <10% | <10% |

| product capacity | 5-6m³/h | 5-6m³/day |

| Input and output conveyor length | 5m / 6m | 5m / 6m |

| Total power | 211.5kw | 211.5kw |

| Heating motor power | 15sets * 11kw | 11sets× 15 kw |

| Cooling motor power | 4sets * 4kw | 4 sets* 4kw |

| Driving motor power | 4sets* 7.5kw | 4sets* 7.5kw |

| Moisture exhaust motor power | 2sets*0.25kw | 2sets*0.25kw |

| Heating consumption | 3500KW | 3500KW |

| Automatic feeding system | optional | optional |

| Temperature detector system | yes | yes |

| Moisture detector system | optional | optional |

| Weight | 150000kgs | 160000kgs |

| Overall size | 44m(L)*4.2m(W)*4.5m(H) | 36m(L)*5.8m(W)*4.5m(H) |

1. Rack structure; The Q234 thickened special-shaped square tube has excellent rigidity, and the overall frame is connected by steel bolts, making installation simple and convenient. Fine machining of the moving parts improves the precision and smoothness of the movement

2. Whole machine motion system; Adopting Taiwan's AirTAC high-precision cylinders and imported pneumatic components. The motion part of Taiwan's HIWIN high-precision linear guide and slider bearings ensure operational accuracy and smoothness. The suction cup is made of imported silicone with good adsorption effect and high wear resistance. The vacuum generator is a self-developed three-level vacuum generator with low air consumption, high vacuum conversion rate, and low noise. Used in conjunction with a vacuum filtration device.

3. Whole machine control system

This equipment control system adopts Siemens S7-1500PLC control system, with internal network Profinet bus control, which can be connected to your company's MES system for grid connection, real-time collection of drying data, and real-time monitoring of equipment operation status.

4 electronic sensors

The electronic sensors of this machine are all made of Japan's Omron OMRON series sensors, which have high accuracy, strong anti-interference ability, and long service life.This veneer dryer gather the features from mesh belt dryer and roller dryer, so that it has both advantages of them.

AUTOMATIC VENEER LOADING MACHINE

Automatically transport the veneer to the designated position, use a suction cup device to absorb the wood veneer and send it to the layering machine, reducing the forklift transportation processransfer the fresh veneer into loader automatcally, the position

AUTOMATIC ABSORB SUCKER

Each suction cup has an independent control unit, which precisely controls the suction cup to adsorb the veneer, ensuring that only one veneer is transported at a time, avoiding the accumulation of veneer during the feeding process, and reducing equipment failure rate

VENEER RESPECTIVE DEVICE

By using automatic veneer respective equipment to accurately transport veneers to different dryer layers, production efficiency is greatly improved, labor is reduced, and labor intensity is much lowered, it's very useful to increase the capacity especially for more layers veneer dryer.

AUTOMATIC STACKING MACHINE FOR DRYER

After the veneer dried, will be transfered to veneer stacker automatically, the Automatic detection system will control the stacking machine to collect veneer according to the grade, reduce workers to collect and down the risk of veneer cracking.

ROLLER CONVEYOR OF DRYER

The veneer position will be corrected in transfing by those roller conveyor, so can collect the veneer orderly, increase the product capacity and reduce labors to stack the veneer soigne

AUTOMATIC FEEDING SYSTEM

This feeding system can load veneer automatically, don't need labor to feed the veneer, espcially for big size veneer, it's easy to damage in feeding by manual, generate a serious wasting, and more useful for the dryer that more than 2 layers, reduce more operators and increase the drying capacity.

This is an optional device, can choose it according to customer demands.

Our veneer dryer machine and plywood machine are exported to many countries like Malaysia,Indonesia, Russia, Turkey ,Brazil, Argentina, Paraguay and so on.

Spindleless peeler

Veneer dryer

Veneer composer

Hot press

Glue spreader

plywood trimming saw

Automatic putty line

Calibrating machine

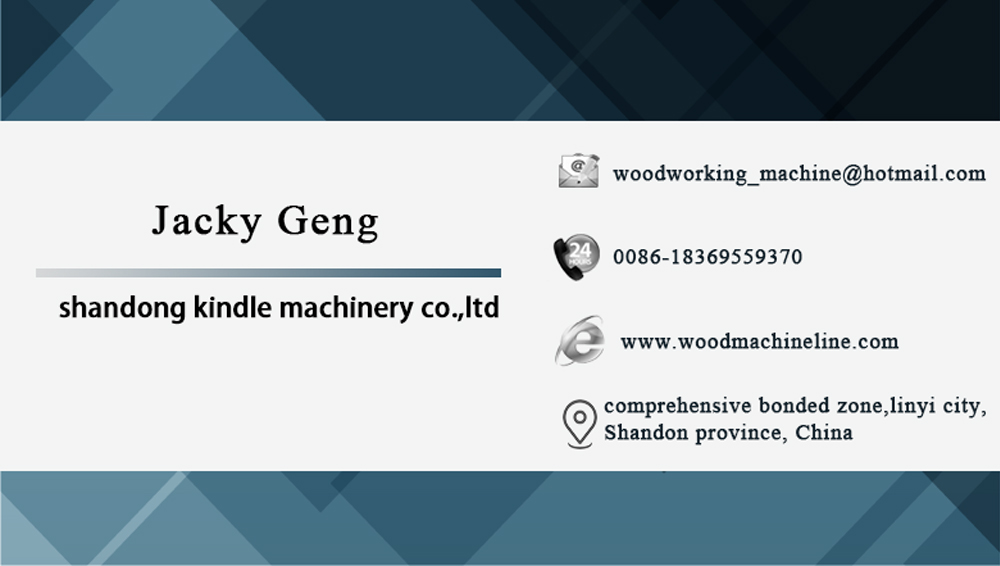

Shandong kindle Machinery manufacture limited company

located in Linyi national Economic and Technological Deve-

lopment Zone, it was founded in 1998 which specialized in

research and development of veneer peeling machine for 26

years. It have obtained more than 60 national patents , it covers more than 30000㎡ area and have 15 R&D technician and 30 professional engineer for installation and machine maintaining.

![]()

We are committed to provide complete solutions for veneer

peeling line, plywood making plant,LVL,block board, PB,OSB production Line etc. Main equipment include: Log cutting saw, log debarker , spindle peeling lathe and spindleless wood veneer peeling machine,veneer dryer, glue spreader,pre-press, hot press, veneer commposer,plywood saw, sanding machine, boiler, and related plant accessories and materials, etc.

![]()

FAQ:

Q1:Are you machine manufacturer or a trading company?

A1: we are a factory which is special for producing veneer peeling machine and plywood machine,Jinduo company own 2 workshops and 1 trading company

Q2:What is the delivery time?

A2:In generally speaking , the complete veneer product line need about 30 days to manufacture after getting deposit.

Q3: what is the maintenance period and what kind of after sale service can you supply?

A3: the machinery part maintenance will be sustained in one year after installation and we have abroad warehouse and office for spare part in brazil and Russia, our engineer will arrive your factory to maintain the machine at first time if have problem.

Q4: what is the payment term?

A4: we can accept TT with 30% deposit and 70% balance against loading bill or 100% irrevocable L/C at sight.

Q5:can we visit your factory?

A6: Jinduo company is next to linyi airport, we can pick you up from airport to our factory at any time, welcome to visit us.