| Capacity: | |

|---|---|

| power: | |

| Temperature: | |

| Availability: | |

GTHG2000-120D

KINDLE

The wood shavings rotary dryer is an efficient combined three-cylinder dryer. Large three-cylinder dryer, usually 6~7 meters long, this new three-cylinder dryer has a compact structure, less floor area, is the same output of one-half of the floor area of one-cylinder drying, reliable work, low energy consumption, high thermal efficiency, good material drying effect, easy to achieve automatic control, less operators.

Machine parameter

1. The Triple cylinder rotary dryer is divided into the inner cylinder, the middle cylinder and the outer cylinder.

2. After the material enters the inner cylinder of the dryer, it will be firstly dispersed evenly and form the sand to a waterfall shape under the turning of the multi-fold sand raising board, and fully contact with the hot air.

3. During the drying process, the materials will enter the middle cylinder of the dryer under the action of the inclined sand-raising board and the hot air, and the sand waterfall will be raised again by the serrated sand raising board to increase the contact area between the sand and the hot air for secondary drying

4.Finally, the dry sand will be exported through the inflow plate of the outer cylinder, and the inflow process is also the further drying of the material, to ensure the comprehensive drying of thesand.

THE ROLLER OF DRYER

Chemical analysis was carried out on the material inspection, according to the requirements of GB700-2006, dryer drum thickness <= 20 mm we use Q245 - A, > 20 mm we use Q245 - B

ROLLER MATERIAL

According to the GB/T 2970-2004 class ii, the range of 60 mm weld edge every board before cutting for ultrasonic flaw detection.

DRYER DRUM WELDING

The dryer cylinder section for toroidal welding, longitudinal along the entire circumference of not more than two weld article number, and shell welds shall be full, the minimum is not lower than the parent metal surface, the top should not be higher than 3mm, feed plate weld should be smooth.Weld edge bite depth should not be greater than 0.5 mm.

NSPECTION

Examination all the parts according to the drawing after processing completion. praying primer, rust preventing paint, and heat resistance paint.

Our veneer dryer machine and plywood machine are exported to many countries like Malaysia,Indonesia, Russia, Turkey ,Brazil, Argentina, Paraguay and so on.

Our veneer dryer machine and plywood machine are exported to many countries like Malaysia,Indonesia, Russia, Turkey ,Brazil, Argentina, Paraguay and so on.

Spindleless peeler

Veneer dryer

Veneer composer

Hot press

Glue spreader

plywood trimming saw

Automatic putty line

Calibrating machine

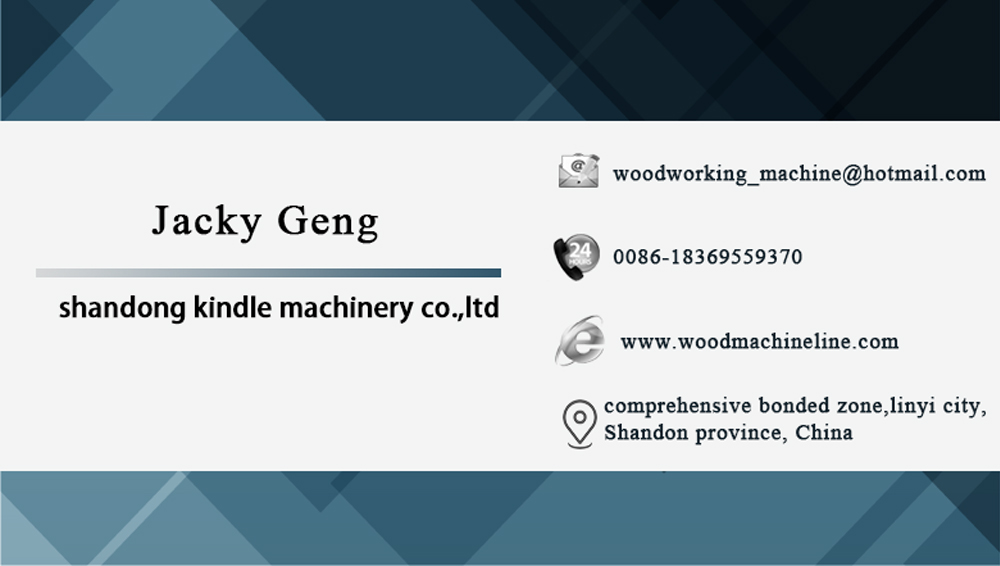

Shandong kindle Machinery manufacture limited company

located in Linyi national Economic and Technological Deve-

lopment Zone, it was founded in 1998 which specialized in

research and development of veneer peeling machine for 26

years. It have obtained more than 60 national patents , it covers more than 30000㎡ area and have 15 R&D technician and 30 professional engineer for installation and machine maintaining.

![]()

We are committed to provide complete solutions for veneer

peeling line, plywood making plant,LVL,block board, PB,OSB production Line etc. Main equipment include: Log cutting saw, log debarker , spindle peeling lathe and spindleless wood veneer peeling machine,veneer dryer, glue spreader,pre-press, hot press, veneer commposer,plywood saw, sanding machine, boiler, and related plant accessories and materials, etc.

![]()

FAQ:

Q1:Are you machine manufacturer or a trading company?

A1: we are a factory which is special for producing veneer peeling machine and plywood machine,Jinduo company own 2 workshops and 1 trading company

Q2:What is the delivery time?

A2:In generally speaking , the complete veneer product line need about 30 days to manufacture after getting deposit.

Q3: what is the maintenance period and what kind of after sale service can you supply?

A3: the machinery part maintenance will be sustained in one year after installation and we have abroad warehouse and office for spare part in brazil and Russia, our engineer will arrive your factory to maintain the machine at first time if have problem.

Q4: what is the payment term?

A4: we can accept TT with 30% deposit and 70% balance against loading bill or 100% irrevocable L/C at sight.

Q5:can we visit your factory?

A6: Jinduo company is next to linyi airport, we can pick you up from airport to our factory at any time, welcome to visit us.