| Maximum log length: | |

|---|---|

| MAX. LOG DIAMETER: | |

| product capacity: | |

| Availability: | |

XQLSX130-50D

KINDLE

The spindle veneer peeling line include one set log conveyor for debarker , one set log debarker, one set log distributor, two sets log conveyor for veneer peeling machine , two sets veneer peeling machine and two sets automatic veneer stacker, this line can increase the veneer product capacity and reduce the workers, one set 4 feet double peeling line can produce 60-80m³ veneer in 8 hours, for this whole line, just need one operator for log debarker, other machines don't need operator, reduce a lot of working strength between log transfer. it's very valuable to establish a automatic plywood factory.

Machine parameter

| Model | YKXQ260-800D |

| Maximum log length | 2600mm |

| Maximum log diameter | Φ800mm |

| Blade size | 2800*180*16mm |

| veneer thickness | 0.6-3.2mm |

| Veneer size | 2600mm*(600mm-1300mm) |

| Veneer degree | 2 degrees |

| product capacity | 40-50m³/day |

| Total power | 125kw |

| operator | 1 person |

| Weight | 23800kgs |

| Overall size | 18000mm*5600mm |

High Efficiency:

Spindle veneer machines enable rapid production of large - scale veneer sheets, significantly boosting output.

Precise Thickness:

These machines ensure consistent veneer thickness with advanced controls, meeting strict quality requirements.

Versatility:

Capable of processing various log diameters and wood species, they are suitable for multiple applications.

Cost - effectiveness:

By reducing material waste and optimizing resource use, spindle veneer machines cut production cost

Automated Operation:

With automatic functions, they decrease manual labor, improving safety and production accuracy.

HYDRAULIC CHAMPING JAW

Adopt double champing jaw to clamp log, when log diameter is bigger, the outside jaw will clamp the log center and when log diameter become small, the ourside jaw will be shrink and the inside jaw continue to clamp the log, in this way, the remainder log diameter can be smaller, same logs.

SPINDLE VENEER PEELER

The spindle veneer peeling machine has many merits. It offers high precision in peeling, resulting in smooth and even veneers. Its structure is stable, ensuring reliable operation. It can handle various types of wood, and has a high peeling efficiency, which boosts productivity.

FEEDING SYSTEM

The feeding system of this spindle veneer peeler adopt high precision servo motor and gear reducer, so can promise the veneer thickness is uniformity and smooth,

VENEER POSITION KNIFE

The cutting knife can be put at any position to cut veneer into correct size, easy to move and adjustable, in this one spindle peeler machine, can get many different size of veneer.

AUTOMATIC LOG LOADER FOR SPINDLE PEELER

This automatic log loader can measure the log center and transfer the log to peeling machine, so the peeling machine champing jaw can clamp the log center automatically, reduce the operater working pressure and save more raw logs, this also can increase the product capacity greatly.

LOG LENGTH ADJUSTED STRUCTURE

Sometimes, the log length is much longer than veneer size, so need to adjust the peeling length according to the log length, in order to promise the log to keep straight, so add this length adjusted structure, in this way, the longer spindle veneer peeling lathe also can produce small size veneer.

CONTROL UNIT FOR PEELING LATHE

Stable and mature control system to promise our spindle veneer lathe can produce high quality veneer and keep the machine working a longer time in a steady condition, the thickness and veneer surface is much better and few problems of machine.

Our log debarker and automatic veneer peeling line are exported to many countries like Malaysia,Indonesia, Russia, Turkey ,Brazil, Argentina, Paraguay and so on.

Spindle peeling machine

Veneer dryer

Veneer composer

Hot press

Glue spreader

plywood trimming saw

Automatic putty line

Calibrating machine

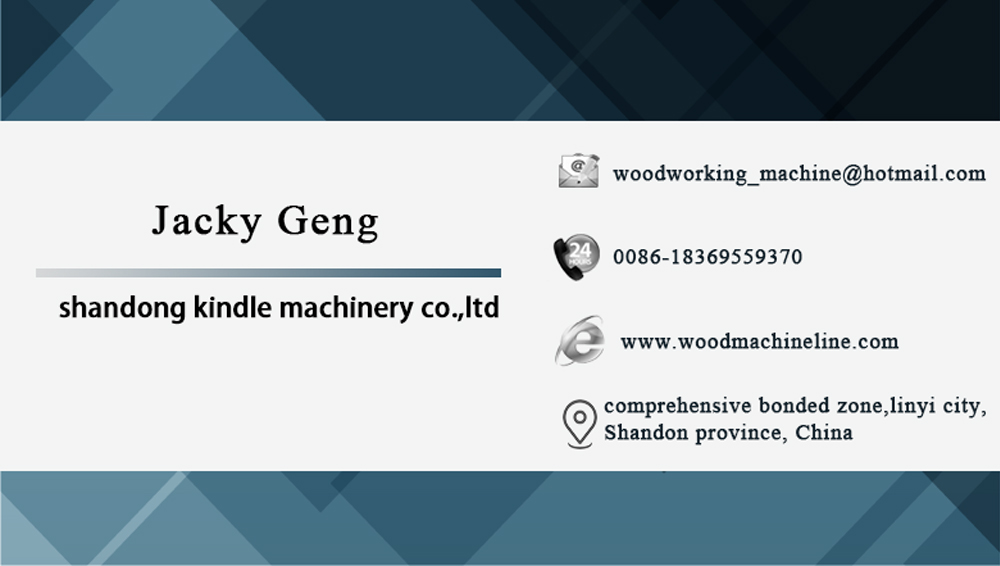

Shandong kindle Machinery manufacture limited company located in Linyi national Economic and Technological Development Zone, it was founded in 1998 which specialized in research and development of veneer peeling machine for 26 years. It have obtained more than 60 national patents , it covers more than 30000 area and have 15 R&D technician and 30 professional engineer for installation and machine maintaining.

We are committed to provide complete solutions for veneer peeling line, plywood making plant,LVL,block board, PB,OSB production Line etc. Main equipment include: Log cutting saw, log debarker , spindle peeling lathe and spindleless wood veneer peeling machine,veneer dryer, glue spreader,pre-press, hot press, veneer commposer,plywood saw, sanding machine, boiler, and related plant accessories and materials, etc.

![]()

FAQ:

Q1:Are you machine manufacturer or a trading company?

A1: we are a factory which is special for producing veneer peeling machine and plywood machine,Jinduo company own 2 workshops and 1 trading company

Q2:What is the delivery time?

A2:In generally speaking , the complete veneer product line need about 30 days to manufacture after getting deposit.

Q3: what is the maintenance period and what kind of after sale service can you supply?

A3: the machinery part maintenance will be sustained in one year after installation and we have abroad warehouse and office for spare part in brazil and Russia, our engineer will arrive your factory to maintain the machine at first time if have problem.

Q4: what is the payment term?

A4: we can accept TT with 30% deposit and 70% balance against loading bill or 100% irrevocable L/C at sight.

Q5:can we visit your factory?

A6: Jinduo company is next to linyi airport, we can pick you up from airport to our factory at any time, welcome to visit us.