| Maximum log length: | |

|---|---|

| MAX. LOG DIAMETER: | |

| shaving size: | |

| Availability: | |

BHXQ260-50OSB

KINDLE

This machine efficiently peels logs into thin, uniform shavings. It features high - speed dual - power systems and automatic spindle mechanisms, enabling smooth operation. For example, it can process logs with diameters of 50 - 500 mm and lengths up to 1400 mm. The linear speed can reach 50 - 80 m/min, and the reference output is around 120 m³/day.

Machine parameter

| Model | JDXQ150-50OSB | JDXQ290-50OSB |

| Maximum log length | 1300mm | 2900mm |

| Maximum log diameter | Φ500mm | Φ500mm |

| Minimum log diameter | Φ45mm | Φ42mm |

| Blade size | 1500*180*16mm | 2900*180*16mm |

| veneer thickness | 0.3-0.8mm | 0.3-0.8mm |

| product capacity | 3m³/h | 6m³/h |

| peeling speed | 150-170m/min | 150-170m/min |

| shaving size | (30-100mm)*width(adjustable) | (30-100mm)*width(adjustable) |

| speed range | 80-240m/min | 80-240m/min |

| Total power | 40.5kw | 70kw |

| Double roller power | 15kw | 2*22kw |

| Single roller power | 15kw | 2*22kw |

| Feeding power | 7.5kw(servo) | 15kw(servo motor) |

| shredder power | 5.5kw | 11kw |

| Weight | 7200kgs | 13000kgs |

| Overall size | 3800*2100*1650mm | 6200*2450*2000mm |

The structure is more solid and stronger , can bark most kind of log no matter hard or soft.

The roller diameter is bigger and have been heat treated, much harder and More wear-resistant

The hydraulic unit part adopt international famous brand, working more reliable.

Support roller can work well with big and curved log, it is very useful in complete peeling line.

Adopt double shredder saw, solve the problem of veneer blocking, increase product efficiency.

SUPPORT ROLLER

INTELLIGENT LUBRICATED SYSTEM

The automatic lubrication system is a smart solution. It precisely delivers lubricants at set intervals, ensuring machinery parts work smoothly. It boosts efficiency, cuts maintenance costs, and extends equipment lifespan

STRETCH HYDRAULIC FEEDING SYSTEM

It employs a unique buffer mechanism that combines mechanical transmission and hydraulic systems. This revolutionary technology for external rotary cutting helps avoid the impact of irregular wood on the machine, thereby extending the overall service life of bearings and key components.

LOG POSITION CORRECTOR

It adopts a hydraulic bilateral synchronous centering mechanism. When the wood is rotating at a high speed, it is prone to deviation. The universal balls on both sides can perform the centering action without stopping the machine, enabling the wood to return to its original position, which greatly improves the production efficiency.

WOOD SHAVING CHIPPER

The size of the wood shavings can be adjusted through the crushing mechanism. The crushing speed can change in real time according to the peeling speed, ensuring that the size of the shavings during the crushing process is relatively stable. Additionally, the width of the wood shavings can also be adjusted according to production requirements.

Our OSB wood shaving machine and automatic veneer peeling line are exported to many countries like Malaysia,Indonesia, Russia, Turkey ,Brazil, Argentina, Paraguay and so on.

Spindle peeling machine

Veneer dryer

Veneer composer

Hot press

Glue spreader

plywood trimming saw

Automatic putty line

Calibrating machine

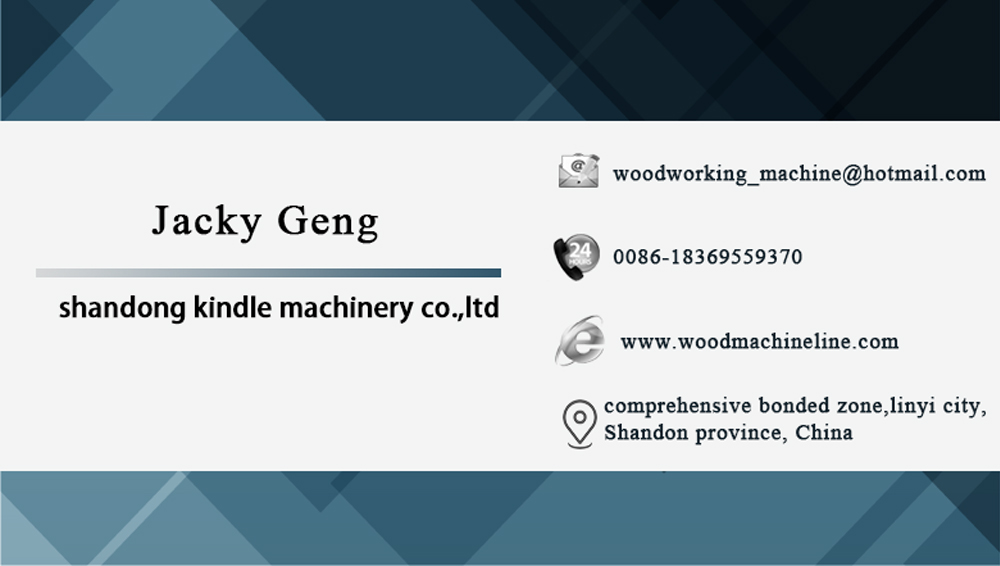

Shandong kindle Machinery manufacture limited company

located in Linyi national Economic and Technological Deve-

lopment Zone, it was founded in 1998 which specialized in

research and development of veneer peeling machine for 26

years. It have obtained more than 60 national patents , it covers more than 30000㎡ area and have 15 R&D technician and 30 professional engineer for installation and machine maintaining.

![]()

We are committed to provide complete solutions for veneer

peeling line, plywood making plant,LVL,block board, PB,OSB production Line etc. Main equipment include: Log cutting saw, log debarker , spindle peeling lathe and spindleless wood veneer peeling machine,veneer dryer, glue spreader,pre-press, hot press, veneer commposer,plywood saw, sanding machine, boiler, and related plant accessories and materials, etc.

![]()

FAQ:

Q1:Are you machine manufacturer or a trading company?

A1: we are a factory which is special for producing veneer peeling machine and plywood machine,Jinduo company own 2 workshops and 1 trading company

Q2:What is the delivery time?

A2:In generally speaking , the complete veneer product line need about 30 days to manufacture after getting deposit.

Q3: what is the maintenance period and what kind of after sale service can you supply?

A3: the machinery part maintenance will be sustained in one year after installation and we have abroad warehouse and office for spare part in brazil and Russia, our engineer will arrive your factory to maintain the machine at first time if have problem.

Q4: what is the payment term?

A4: we can accept TT with 30% deposit and 70% balance against loading bill or 100% irrevocable L/C at sight.

Q5:can we visit your factory?

A6: Jinduo company is next to linyi airport, we can pick you up from airport to our factory at any time, welcome to visit us.