| Maximum log length: | |

|---|---|

| MAX. LOG DIAMETER: | |

| product capacity: | |

| Availability: | |

LSX130-50DU

KINDLE

VENEER PEELING LINE

The veneer peeling line include one set log conveyor for debarker , one set log debarker, one set log distributor, two sets log conveyor for veneer peeling machine , two sets veneer peeling machine and two sets automatic veneer stacker, this line can increase the veneer product capacity and reduce the workers, it streamlines the peeling process from log loading and centering to continuous veneer cutting ensuring minimal downtime and maximum resource utilization.Perfect for large-scale plywood or laminated wood production, the Double Peeling Line delivers unmatched productivity, cost-effectiveness, and reliability for modern wood processing facilities. Kindle Group's 4 feet veneer peeling line is the preferred solution for the wood processing industry. It has won the trust and praise of customers for its excellent performance, efficient production and high-quality service.Choosing Kindle Group means choosing a more efficient, precise and excellent future for wood processing.

| 1 | log conveyor for debarker | 5 | log edge trimming saw |

| 2 | wood waste conveyor from log debarker | 6 | log ladder conveyor for peeling machine |

| 3 | log debarker-heavy model | 7 | remanent log conveyor after peeling |

| 4 | log distributor conveyor | 8 | automatic veneer peeling machine |

| 9 | Vacuum absorbing automatic veneer stacker |

Machine parameter

| Model | XQLSX130-70D |

| Maximum log length | 1300mm |

| Maximum log diameter | Φ700mm |

| Blade size | 1600*180*16mm |

| veneer thickness | 0.6-3.6mm |

| Veneer size | 1300mm*(600mm-2600mm) |

| Veneer degree | 3 degrees |

| product capacity | 60-80m³/day |

| Total power | 125kw |

| operator | 1-2person |

| Weight | 28600kgs |

| Overall size | 24000mm*5600mm |

Only one person is required to operate the entire production line, save people and reducing working intensity

Adopt German SIKE brand electric photo-switch detector,more stable and not easy to broke down.

This line can run smoothly and few problem in working, don't need so much maintenance.

The daily production output can increase 30-40% than regular peeling line, increase the working efficiency

More rational layout of this veneer line, save installation area and more safety in working.

LOG CONVEYOR FOR CUTTING SAW

This part is used to feed raw log to log cutter, the log is not round and diameter is bigger, so the chain and structure need stronger and more solid.

The ladder converyor is used to separate log in single, so can ensure only one log can be put in log debarker, improve the automatic level.

AUTOMATIC LOG CUTTING SAW

This part is used to cut 8 feet log into 2 pieces 4 feet length and trimming the log edge at same time. the cutting type adopt saw blade,diameter can be 1200mm, the cutting efficiency is much higher than normal model and the cut gap is very thin.

Each blade is drived by one 18.5kw motor, power enough for big and hard log.

LOG DEBARKER-HEAVY MODEL

The log debarker adopt heavy model, the support roller is helpful to process curved log and guarantee the finished log can drop out of the debarker smoothly, so this whole peelng line can working smoothly, don't need operator to handle it. and this heavy model debarker is more powerful and stronger, it's easy to deal with different kind of log.

LOG DISTRIBUTING CONVEYOR

This conveyor is used to transfer log to different machines according to the log diameter. It has some high precision detector to collect the singal and transfer to PLC, so can transfer log automatically. reduce the work strength of labor, also increase the working efficiency greatly.

LOG CONVEYOR FOR PEELING MACHINE

The log position corrector can transfer log into the middle of peeling machine blade, the plane conveyor is used to store log after debarking machine,the declining conveyor can separate log into single and feed it to peeling machine, in this way, the peeling machine don't need operator, it can working full automatically.

VENEER PEELING MACHINE- AUTO MODEL

The Peeling machine speed can be 40-100m/min and don't need operator, increase the veneer product capacity and reduce operator in this line, The regular log diameter is 500mm and the Maximum diameter of log can be 700mm, veneer thickness can be 0.6-3.6mm, precision of veneer thickness can be ±0.075mm, this is the main part in this veneer product line.

AUTOMATIC VENEER STACKER

Because the speed of peeling machine can be 100m/min much faster than manual stacking, so have to adopt this auto stacker, this stacker speed can be 40-120m/min, the veneer thickness can be 0.8-3.6mm. adopt vacuum suction fans to transfer veneer. This stacker can separate different degree veneer into independent stacks, you can set the hole size based on degree, it's very popular in automatic veneer product line.

Our log debarker and automatic veneer peeling line are exported to many countries like Malaysia,Indonesia, Russia, Turkey ,Brazil, Argentina, Paraguay and so on.Welcome contact us for more information

Spindle peeling machine

Veneer dryer

Veneer composer

Hot press

Glue spreader

plywood trimming saw

Automatic putty line

Calibrating machine

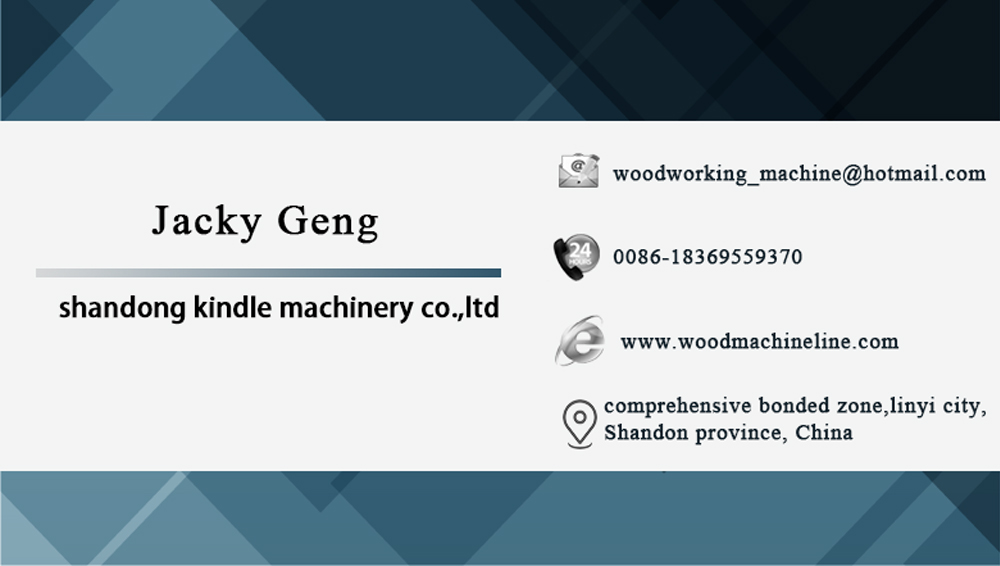

KINDLE COMPANY

Shandong kindle Machinery manufacture limited company located in Linyi national Economic and Technological Development Zone, it was founded in 1998 which specialized in research and development of veneer peeling machine for 26 years. It have obtained more than 60 national patents , it covers more than 30000㎡ area and have 15 R&D technician and 30 professional engineer for installation and machine maintaining.

We are committed to provide complete solutions for veneer peeling line, plywood making plant,LVL,block board, PB,OSB production Line etc. Main equipment include: Log cutting saw, log debarker , spindle peeling lathe and spindleless wood veneer peeling machine,veneer dryer, glue spreader,pre-press, hot press, veneer commposer,plywood saw, sanding machine, boiler, and related plant accessories and materials, etc.

![]()

FAQ:

Q1:Are you machine manufacturer or a trading company?

A1: we are a factory which is special for producing veneer peeling machine and plywood machine,Jinduo company own 2 workshops and 1 trading company

Q2:What is the delivery time?

A2:In generally speaking , the complete veneer product line need about 30 days to manufacture after getting deposit.

Q3: what is the maintenance period and what kind of after sale service can you supply?

A3: the machinery part maintenance will be sustained in one year after installation and we have abroad warehouse and office for spare part in brazil and Russia, our engineer will arrive your factory to maintain the machine at first time if have problem.

Q4: what is the payment term?

A4: we can accept TT with 30% deposit and 70% balance against loading bill or 100% irrevocable L/C at sight.

Q5:can we visit your factory?

A6: Jinduo company is next to linyi airport, we can pick you up from airport to our factory at any time, welcome to visit us.