| Maximum log length: | |

|---|---|

| MAX. diameter: | |

| Roller type: | |

| Availability: | |

BPJ6000R-35D

KINDLE

The drum-type roller log debarker utilizes mechanical friction to efficiently remove bark by rotating logs to collide and rub against each other. Equipped with wear-resistant lining plates and spiral feeding devices, it adapts to logs of various diameters with high processing capacity. Featuring robust construction, stable operation, and easy maintenance, it is widely used in pulp, fiberboard, and other industries for log pretreatment.

Machine parameter

| Model | BPJ600R-45D | BPJ800R-45D | BPJ1000R-45D |

| Maximum veneer length | 4000mm | 6000mm | 8000mm |

| Maimum log diameter | φ20-φ450mm | φ20-φ450mm | φ20-φ450mm |

| Barking rate | 98% | 98% | 98% |

| Power | 7.5kw*2sets | 7.5kw*4sets | 7.5kw*6sets |

| Capacity | 3-5t/h | 8-10t/h | 10-15t/h |

| Rate of timber loss | 1.5% | 1.5% | 1.5% |

| Weight | 3000kg | 6000kg | 9000kg |

| Size | 7000*1300*1600mm | 13000*1800*1800mm | 19000*2000*2000mm |

1. Applicable raw material.Equipment size can be customized according to wood length and diameter

2.Final Product.The damage rate of wood is low, and the peeling effect is more than 98%.

3.log construction.peeled wood can be used for wooden houses, beams and columns, Bridges and other traditional building structures.

4.A wide range of applications after tree peeling:Finished products are widely used in fuel, construction, greening, papermaking, support, furniture and so on

SPECIAL MATERIAL OF ROLLER

The roller adopt manganese steel to increase the hardness and wearness, and the roller is designed as free assemble, easy to maintain and exchange.

ROLLER TEETH

The roller teeth adopt manganese steel and with trajectory shape to reduce the wearness , increase the working time and the efficiency of skin barking.

THICKNESS OF ROLLER STEEL

The thickness of roller steel is 16mm, solid and strong enough for big diameter roller, not easy to broken, increase the working life and not easy to distortion, so can ensure the barking efficiency.

THICK STEEL OF LOG SKIN MOVING PLATE

The thickness of log skin moving plate is 20mm, solid enough for log skin peeling and with a longer life working, heavy and strong frame to ensure the roller log peeler quality and efficiency.

Our roller log debarking machine,log debarker and automatic veneer peeling line are exported to many countries like Malaysia,Indonesia, Russia, Turkey ,Brazil, Argentina, Paraguay and so on.

SPIDLELESS LOG DEBARKER

CIRCLE LOG BARKING MACHINE

Veneer peeling line

Veneer dryer

Veneer composer

Hot press

Glue spreader

plywood trimming saw

Automatic putty line

Calibrating machine

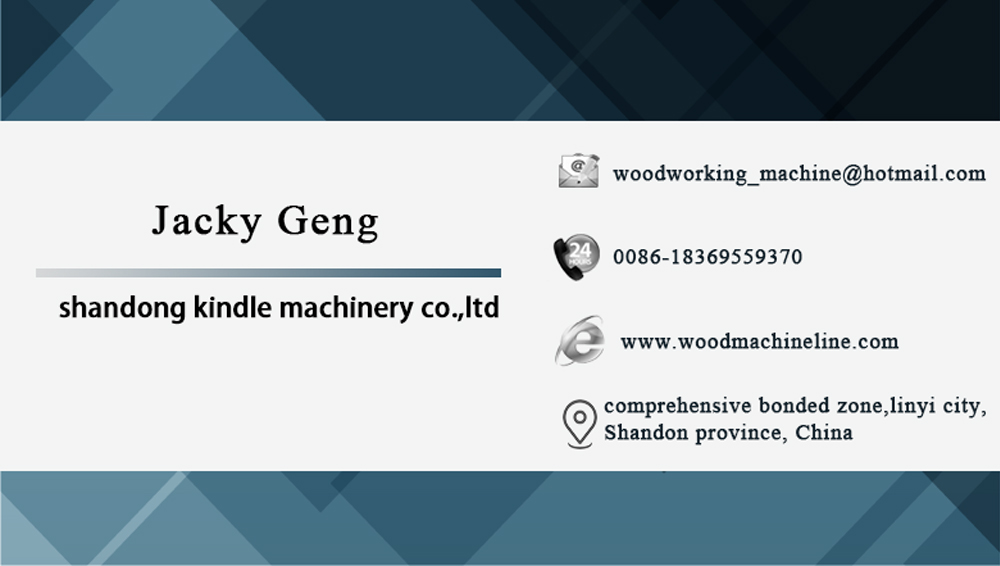

Shandong kindle Machinery manufacture limited company

located in Linyi national Economic and Technological Deve-

lopment Zone, it was founded in 1998 which specialized in

research and development of veneer peeling machine for 26

years. It have obtained more than 60 national patents , it covers more than 30000㎡ area and have 15 R&D technician and 30 professional engineer for installation and machine maintaining.

![]()

We are committed to provide complete solutions for veneer

peeling line, plywood making plant,LVL,block board, PB,OSB production Line etc. Main equipment include: Log cutting saw, log debarker , spindle peeling lathe and spindleless wood veneer peeling machine,veneer dryer, glue spreader,pre-press, hot press, veneer commposer,plywood saw, sanding machine, boiler, and related plant accessories and materials, etc.

![]()

Q1:Are you machine manufacturer or a trading company?

A1: we are a factory which is special for producing veneer peeling machine and plywood machine,Jinduo company own 2 workshops and 1 trading company

Q2:What is the delivery time?

A2:In generally speaking , the complete veneer product line need about 30 days to manufacture after getting deposit.

Q3: what is the maintenance period and what kind of after sale service can you supply?

A3: the machinery part maintenance will be sustained in one year after installation and we have abroad warehouse and office for spare part in brazil and Russia, our engineer will arrive your factory to maintain the machine at first time if have problem.

Q4: what is the payment term?

A4: we can accept TT with 30% deposit and 70% balance against loading bill or 100% irrevocable L/C at sight.

Q5:can we visit your factory?

A6: Jinduo company is next to linyi airport, we can pick you up from airport to our factory at any time, welcome to visit us.