| Total power: | |

|---|---|

| Weight: | |

| Maximum depth: | |

| Availability: | |

JDMD7180-MK

KINDLE

The veneer knots fixing machine adaptive suction mechanism securely holds veneer sheets during operation, preventing slippage and ensuring precise alignment of replacement patches, while its user-friendly interface allows operators to easily configure settings for different veneer thicknesses and types. Built with durable stainless-steel components and a robust frame, the machine withstands the rigors of continuous industrial use, requiring minimal maintenance. It integrates seamlessly with existing plywood production lines, enhancing overall yield by transforming defective veneer into high-grade material suitable for premium applications. By combining automation, accuracy, and reliability, this fixing machine ensures that veneer plywood manufacturers can deliver products with uniform appearance and structural integrity, while significantly improving production efficiency and cost-effectiveness. Ideal for both large-scale factories and medium-sized operations, it sets a new standard for defect repair in veneer processing, enabling businesses to maintain competitive edges in quality and productivity.

Machine parameter

Machine parameter

| Model | JDMD7180-MK | JDMD7181-MK |

| Maximum working depth | 780mm | 780mm |

| Mending veneer thickness | 1.0-3.0mm | 1.0-3.0mm |

| Mending veneer size | 40*60mm | 40*100mm |

| Mending speed | 3-5s/time | 3-5s/time |

| Weight | 1300kgs | 1500kgs |

| Power | 4.25kw | 4.25kw |

1. A pneumatic booster cylinder may significantly reduce personnel and make operations easier.

2. With male and female molds, punching scars, and cutting patches, a single device can.

3. The mold size and form can be modified based on customer specifications.

4. The machine frame is welded with profiles and steel plates, ensuring stability and durability.

5. Multi-size molds can fix wood veneer scar holes of different sizes.

6. High-quality molds, with high punching precision and good durability.

Multi Thickness Compatibility

Handles veneer sheets from 0.2mm to 6mm in thickness, suitable for softwoods and hardwoods. Leverages advanced hydraulic or pneumatic systems to achieve rapid defect removal and patching, with a cycle time as low as 2 seconds per patch—6-10 times faster than manual repair.

Laser Guidance System

Equipped with a red crosshair laser positioning module for pinpoint accuracy, ensuring precise alignment of patches to defects, even in complex shapes.

Customizable Molds

No Glue/Tape Dependency

Innovative mechanical design allows for direct punching and embedding of patches without additional adhesives, minimizing material costs and environmental impact.

Durabl Components

High-quality steel molds and hydraulic/pneumatic systems designed for long-term use, with minimal wear and tear. For example, lifespan exceeds 6 months for 4mm-thick veneer and up to 1.5 years for thinner sheets.

High-quality steel molds and hydraulic/pneumatic systems designed for long-term use, with minimal wear and tear. For example, lifespan exceeds 6 months for 4mm-thick veneer and up to 1.5 years for thinner sheets.

Our veneer dryer machine and plywood machine are exported to many countries like Malaysia,Indonesia, Russia, Turkey ,Brazil, Argentina, Paraguay and so on. If there have any machines you are interested in ,please click the picture to check the details.

Spindleless peeler

Spindle peeler

Veneer composer

Hot press

Glue spreader

plywood trimming saw

Automatic putty line

Calibrating machine

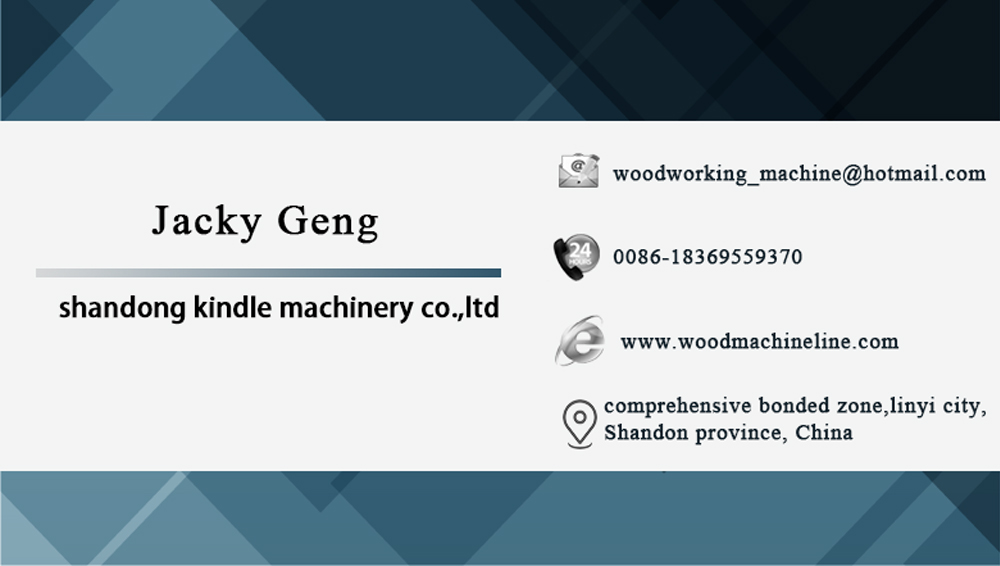

Shandong kindle Machinery manufacture limited company

located in Linyi national Economic and Technological Deve-

lopment Zone, it was founded in 1998 which specialized in

research and development of veneer peeling machine for 26

years. It have obtained more than 60 national patents , it covers more than 30000 area and have 15 R&D technician and 30 professional engineer for installation and machine maintaining.

![]()

We are committed to provide complete solutions for veneer

peeling line, plywood making plant,LVL,block board, PB,OSB production Line etc. Main equipment include: Log cutting saw, log debarker , spindle peeling lathe and spindleless wood veneer peeling machine,veneer dryer, glue spreader,pre-press, hot press, veneer commposer,plywood saw, sanding machine, boiler, and related plant accessories and materials, etc.

![]()

FAQ:

Q1:Are you machine manufacturer or a trading company?

A1: we are a factory which is special for producing veneer peeling machine and plywood machine,Jinduo company own 2 workshops and 1 trading company

Q2:What is the delivery time?

A2:In generally speaking , the complete veneer product line need about 30 days to manufacture after getting deposit.

Q3: what is the maintenance period and what kind of after sale service can you supply?

A3: the machinery part maintenance will be sustained in one year after installation and we have abroad warehouse and office for spare part in brazil and Russia, our engineer will arrive your factory to maintain the machine at first time if have problem.

Q4: what is the payment term?

A4: we can accept TT with 30% deposit and 70% balance against loading bill or 100% irrevocable L/C at sight.

Q5:can we visit your factory?

A6: Jinduo company is next to linyi airport, we can pick you up from airport to our factory at any time, welcome to visit us.