| Weight : | |

|---|---|

| Feeding speed: | |

| Grinding width: | |

| Availability: | |

SHVG-216

KINDLE

A robust steel frame and sealed lubrication system ensure stable performance and minimal maintenance even in dusty, high-moisture workshop environments, while the integrated dust collection system keeps the working area clean and safe. Compatible with various adhesive types, including PVA and hot-melt glue, the machine supports both straight and beveled edge joints, making it ideal for producing large-scale veneer sheets used in furniture, cabinetry, and architectural paneling. This reliable, automated solution enhances material utilization, reduces waste, and delivers consistent high-quality joints, positioning it as a key asset for modern woodworking factories aiming to optimize efficiency and output in veneer processing.

Machine parameter

| Model | Double Head Veneer Grinder | Single Head Veneer Grinder |

| Feeding speed | 3.57-35.7m/min | 3.57-35.7m/min |

| Grinding thickness | 0.8-5.0mm | 0.8-5.0mm |

| Grinding belt line speed | 2051m/min | 2051m/min |

| Grinding width | 5-40mm | 5-40mm |

| Veneer length | 700-1300mm | 700-1300mm |

| Total Power | 16.5kw | 9KW |

| Productivity | 800-1100 piece/h (four spell veneer) | 800-1100 piece/h (four spell veneer) |

| Overall dimension | 2500*2200*1600mm | 2500*2200*1600mm |

1. Delivers ultra-precise grinding with 2μm accuracy for sharp blades.

2. Dual-end design cuts processing time by 50% for high-efficiency output.

3. Automatic alignment and PLC control reduce setup time and manual effort.

4. Heavy-duty build and sealed lubrication ensure durability in tough workshops.

5. Versatile compatibility with various blade types, materials, and sizes.

PLC Control System

A intuitive touchscreen interface allows operators to input grinding parameters with ease. The system stores multiple processing programs for quick switchovers between different blade types

Sealed Lubrication System

Automatic lubrication of moving parts reduces friction and wear, while a fully enclosed design protects internal components from wood chips and dust, enhancing reliability in harsh workshop environments.

Heavy Duty Frame

Sealed Lubrication System

Automatic lubrication of moving parts reduces friction and wear, while a fully enclosed design protects internal components from wood chips and dust, enhancing reliability in harsh workshop environm

Our veneer dryer machine and plywood machine are exported to many countries like Malaysia,Indonesia, Russia, Turkey ,Brazil, Argentina, Paraguay and so on. If there have any machines you are interested in ,please click the picture to check the details.

Spindleless peeler

Spindle peeler

Veneer composer

Hot press

Glue spreader

plywood trimming saw

Automatic putty line

Calibrating machine

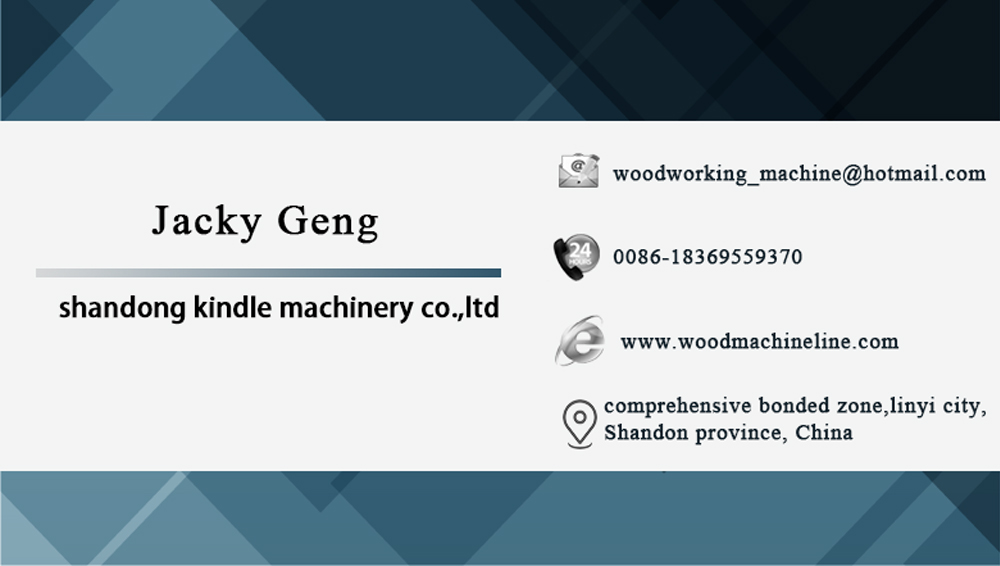

Shandong kindle Machinery manufacture limited company

located in Linyi national Economic and Technological Deve-

lopment Zone, it was founded in 1998 which specialized in

research and development of veneer peeling machine for 26

years. It have obtained more than 60 national patents , it covers more than 30000 area and have 15 R&D technician and 30 professional engineer for installation and machine maintaining.

![]()

We are committed to provide complete solutions for veneer

peeling line, plywood making plant,LVL,block board, PB,OSB production Line etc. Main equipment include: Log cutting saw, log debarker , spindle peeling lathe and spindleless wood veneer peeling machine,veneer dryer, glue spreader,pre-press, hot press, veneer commposer,plywood saw, sanding machine, boiler, and related plant accessories and materials, etc.

![]()

FAQ:

Q1:Are you machine manufacturer or a trading company?

A1: we are a factory which is special for producing veneer peeling machine and plywood machine,Jinduo company own 2 workshops and 1 trading company

Q2:What is the delivery time?

A2:In generally speaking , the complete veneer product line need about 30 days to manufacture after getting deposit.

Q3: what is the maintenance period and what kind of after sale service can you supply?

A3: the machinery part maintenance will be sustained in one year after installation and we have abroad warehouse and office for spare part in brazil and Russia, our engineer will arrive your factory to maintain the machine at first time if have problem.

Q4: what is the payment term?

A4: we can accept TT with 30% deposit and 70% balance against loading bill or 100% irrevocable L/C at sight.

Q5:can we visit your factory?

A6: Jinduo company is next to linyi airport, we can pick you up from airport to our factory at any time, welcome to visit us.