| Weight : | |

|---|---|

| Load capacity: | |

| Size: | |

| Availability: | |

LF-216

KINDLE

Workpiece Positioning Table

Its robust construction supports substantial load capacities while maintaining pinpoint stability during elevation, ensuring secure positioning of delicate or oversized panels without surface deformation. The intuitive control system enables millimeter-level accuracy for alignment with CNC machinery, laser cutters, or automated packaging lines, significantly reducing manual measurement errors. Engineered with energy-efficient hydraulic synchronization technology, it minimizes power consumption during continuous operation while outperforming conventional models in speed consistency. The corrosion-resistant modular design simplifies maintenance and allows configuration upgrades for specialized applications like temperature-controlled environments. By eliminating forklift dependencies and worker strain during height transitions, it enhances workshop safety compliance while achieving 30% faster production cycle times. Customizable platform dimensions and anti-static surface treatments cater specifically to composite panel processors, ensuring compatibility with both metallic and non-metallic sheet materials across multiple industrial applications.

Machine parameter

Machine parameter

| Model | LF-216 |

| Table-board dimension | 2400×1250mm |

| Weight | 800kgs |

| Stroke | 460mm |

| Mini height | 1800mm |

| Max height | 2050mm |

| Cylinder | Φ125mm |

| Power | 3kw 380V-50Hz 3phase |

| Size | 2500×1300×460mm |

1. Surface treatment, shot blasting and stoving varnish with anti-corrosion function.

2. High quality pump station makes scissor lift table lifts and fall very stable.

3. Anti-pinch scissor design; main pin-roll place adopts self-lubricating design which prolong life span.

4. Removable lifting eye to help lift the table and install.

5. Heavy duty cylinders with drainage system and check valve to stop the lift table dropping in case of hose burst.

6. Pressure relief valve prevent overload operation; Flow control valve make descent speed adjustable.

7. Equipped with aluminum safety sensor under the platform for anti-pinch while dropping.

Oil Cylinder

Leak-proof oil-sealed oil cylinder, with stronger load-bearing capacity and stable performance. Fully enclosed oil cylinder, equipped with overload protection device, can effectively prevent overloading, good sealing performance and easy maintenance.

Powerful Motor

Power is transmitted through hydraulic oil, with greater stability and load capacity; the hydraulic pump station has reverse cut-off to prevent reverse flow of oil flow and emergency descent of the platform.

Controller

Lifting Cylinder

Customized cylinder, each cylinder has 3 sets of imported seals, and has been tested; lifting speed is faster and cargo capacity is larger.

Scissor Support Rod

High-strength steel is used, and composite sleeves are added to the support rod sleeve to increase stability and reduce friction. The scissor fork is made of high-quality steel. It refuses to cut corners and cut materials to ensure the firmness of the product.

Platform Table Size

All the running section of the wood chipper is controlled by one combined control panel. It is equipped with infeed, outfeed, feed reverse, oil pump and emergency stop control buttons. All the control panel have motor protection function. For security, there is remote controlling for choice. It is a effective solution to protect the wood chipper operators.

Our veneer dryer machine and plywood machine are exported to many countries like Malaysia,Indonesia, Russia, Turkey ,Brazil, Argentina, Paraguay and so on. If there have any machines you are interested in ,please click the picture to check the details.

Spindleless peeler

Spindle peeler

Veneer composer

Hot press

Glue spreader

plywood trimming saw

Automatic putty line

Calibrating machine

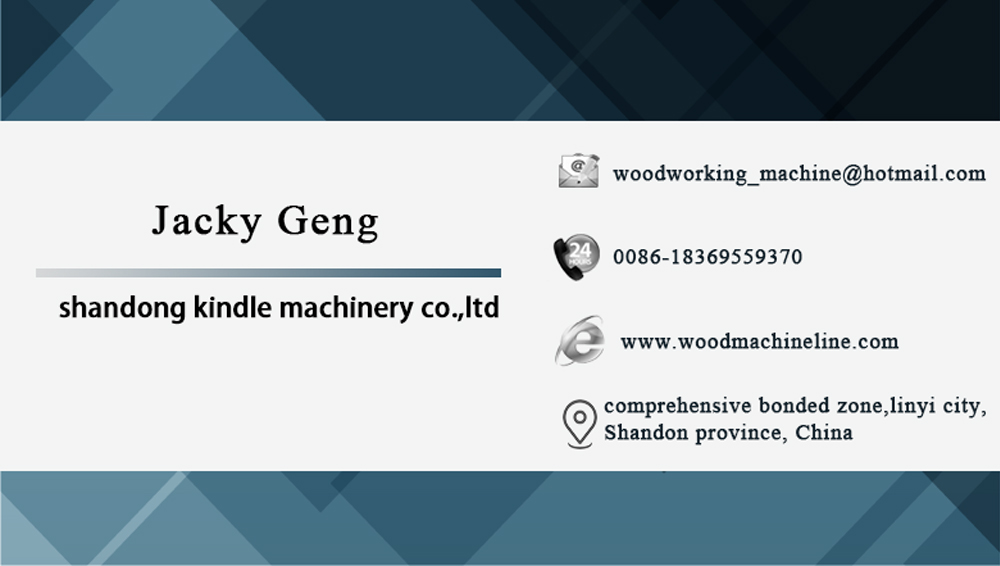

Shandong kindle Machinery manufacture limited company

located in Linyi national Economic and Technological Deve-

lopment Zone, it was founded in 1998 which specialized in

research and development of veneer peeling machine for 26

years. It have obtained more than 60 national patents , it covers more than 30000 area and have 15 R&D technician and 30 professional engineer for installation and machine maintaining.

![]()

We are committed to provide complete solutions for veneer

peeling line, plywood making plant,LVL,block board, PB,OSB production Line etc. Main equipment include: Log cutting saw, log debarker , spindle peeling lathe and spindleless wood veneer peeling machine,veneer dryer, glue spreader,pre-press, hot press, veneer commposer,plywood saw, sanding machine, boiler, and related plant accessories and materials, etc.

![]()

FAQ:

Q1:Are you machine manufacturer or a trading company?

A1: we are a factory which is special for producing veneer peeling machine and plywood machine,Jinduo company own 2 workshops and 1 trading company

Q2:What is the delivery time?

A2:In generally speaking , the complete veneer product line need about 30 days to manufacture after getting deposit.

Q3: what is the maintenance period and what kind of after sale service can you supply?

A3: the machinery part maintenance will be sustained in one year after installation and we have abroad warehouse and office for spare part in brazil and Russia, our engineer will arrive your factory to maintain the machine at first time if have problem.

Q4: what is the payment term?

A4: we can accept TT with 30% deposit and 70% balance against loading bill or 100% irrevocable L/C at sight.

Q5:can we visit your factory?

A6: Jinduo company is next to linyi airport, we can pick you up from airport to our factory at any time, welcome to visit us.