| Weight : | |

|---|---|

| Motor speed: | |

| Motor power: | |

| Availability: | |

BX-216

KINDLE

WOOD CHIPPER SHREDDER

Designed for both stationary and mobile operations (with options for trailer mounting or self-propulsion in some models), this chipper shredder is ideal for forestry sites, sawmills, and recycling facilities, streamlining waste management and raw material preparation. Its ability to produce uniform chips reduces downstream processing costs, making it a cost-effective solution for industries that rely on consistent wood chip quality. Whether used for commercial wood processing or residential land clearing, the Industrial Electric Wood Chipper Shredder combines power, precision, and durability to deliver reliable performance and optimal results.

Machine parameter

Machine parameter

| Model | BX-216 | BX-218 |

| Wood chipper own size | 2600*2100*1430mm | 3000*2000*1500mm |

| Weight | 4.5ton | 8ton |

| Production capacity | Wood chips 5-8t/h | Wood chips 8-15t/h |

| Crushed chips size | 30/20-25mm | 30/20-25mm |

| Feeding size | 300*600mm | 400*700mm |

| Max processed diameter | 240mm | 380mm |

| Knife rod diameter | 650mm | 800mm |

| Fly-knife number | 4pcs | 6pcs |

| Main motor power | 55kw | 110kw |

| Motor speed | 592rpm | 650rpm |

1. New design blade rotor,blades are easy to replaceable.

2. Cover of crushing chamber could be opened by hydraulic,ease for maintenance and changeble blades.

3. Screen mesh size is customized for different requirements on size of end product. Hydraulic buffer system ensures smooth operation.

4. Reverse feeding device,belt conveyor can be reversed positively.This device can protect machine, when large wood is encountered.

5. Higher capacity than the traditional type,larger feeding size,could chipping log diameter 230-500mm.

Heavy-Duty Steel Construction

The robust steel frame and housing ensure durability even for tough wood materials (up to 3 inches in diameter). Powder-coated finish resists rust and weathering, ideal for outdoor use.

Powerful Motor

Motor of drum wood chipper use Siemens Brand. This kind of motor is frequency and has thick copper coil, it won't be burned due to instantaneous current when entering long wood log.

Hydraulic System

High Quality Blade

The material of blade is Manganese steel, not carbon steel, more hard and anti-wearing, it is thick blade, life is long. Even a 8mm iron nails gone inside is no problem. Knife roller with 2-4 knifes which can be adjusted up and down based on the thickness of wood chips required

Feeding Cuter

Wood chipper machine contains 4m long feeding belt conveyor, when conveying logs, the speed can be adjusted also it can connect with outlet conveyor to transport away crushed wood chips.

Wood chipper machine contains 4m long feeding belt conveyor, when conveying logs, the speed can be adjusted also it can connect with outlet conveyor to transport away crushed wood chips.

Control Panel

All the running section of the wood chipper is controlled by one combined control panel. It is equipped with infeed, outfeed, feed reverse, oil pump and emergency stop control buttons. All the control panel have motor protection function. For security, there is remote controlling for choice. It is a effective solution to protect the wood chipper operators.

Our veneer dryer machine and plywood machine are exported to many countries like Malaysia,Indonesia, Russia, Turkey ,Brazil, Argentina, Paraguay and so on. If there have any machines you are interested in ,please click the picture to check the details.

Spindleless peeler

Spindle peeler

Veneer composer

Hot press

Glue spreader

Plywood trimming saw

Automatic putty line

Calibrating machine

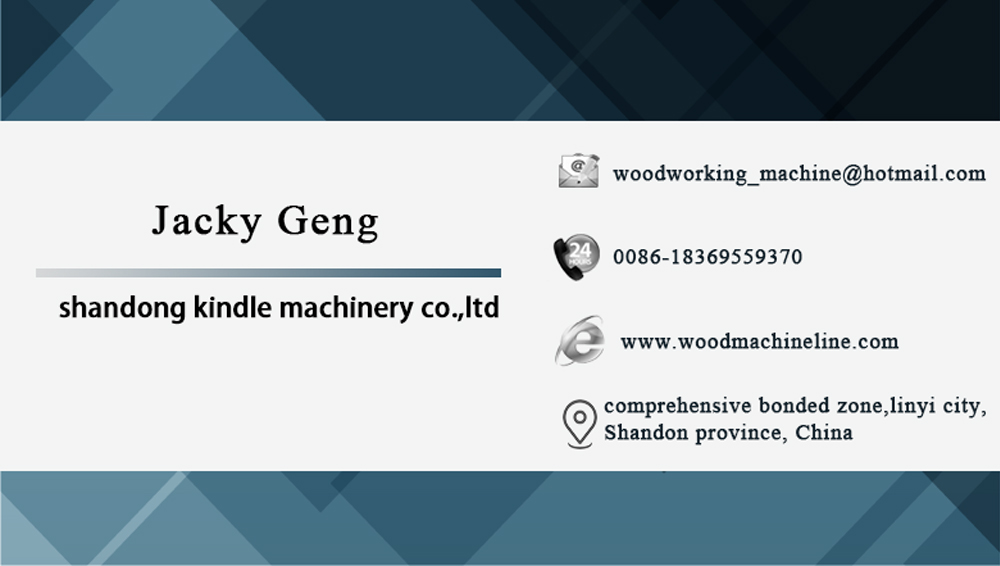

Shandong kindle Machinery manufacture limited company

located in Linyi national Economic and Technological Deve-

lopment Zone, it was founded in 1998 which specialized in

research and development of veneer peeling machine for 26

years. It have obtained more than 60 national patents , it covers more than 30000 area and have 15 R&D technician and 30 professional engineer for installation and machine maintaining.

![]()

We are committed to provide complete solutions for veneer

peeling line, plywood making plant,LVL,block board, PB,OSB production Line etc. Main equipment include: Log cutting saw, log debarker , spindle peeling lathe and spindleless wood veneer peeling machine,veneer dryer, glue spreader,pre-press, hot press, veneer commposer,plywood saw, sanding machine, boiler, and related plant accessories and materials, etc.

![]()

FAQ:

Q1:Are you machine manufacturer or a trading company?

A1: we are a factory which is special for producing veneer peeling machine and plywood machine,Jinduo company own 2 workshops and 1 trading company

Q2:What is the delivery time?

A2:In generally speaking , the complete veneer product line need about 30 days to manufacture after getting deposit.

Q3: what is the maintenance period and what kind of after sale service can you supply?

A3: the machinery part maintenance will be sustained in one year after installation and we have abroad warehouse and office for spare part in brazil and Russia, our engineer will arrive your factory to maintain the machine at first time if have problem.

Q4: what is the payment term?

A4: we can accept TT with 30% deposit and 70% balance against loading bill or 100% irrevocable L/C at sight.

Q5:can we visit your factory?

A6: Jinduo company is next to linyi airport, we can pick you up from airport to our factory at any time, welcome to visit us.