| Maximum veneer length: | |

|---|---|

| Sewing Thickness: | |

| splicing Speed: | |

| Availability: | |

JDPB260V

KINDLE

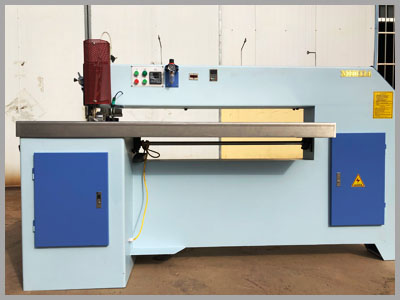

This machine uses a hot - air tube and glue - wire splicing technique. It features a variable - frequency speed regulator, allowing for easy adjustment of the operation speed, which benefits both new and experienced workers. The widened stainless - steel tabletop facilitates smooth feeding of veneers. With thickened heating tubes, it provides sufficient heat for better glue - wire melting, and the replacement cost is relatively low. It is suitable for various veneers, like solid wood and engineered wood, and can handle large - sized boards.

Machine parameter

| Model | PFJ130Y-4V |

| Veneer thickness | 0.3-4.0mm |

| Splicing width | 1350mm |

| Splicing speed | 10-15m/min |

| Working table height | 900mm |

| Motor power | 0.75kw |

| Heater power | 400w |

| Dimension | 2450*650*1300mm |

| Weight | 480kg |

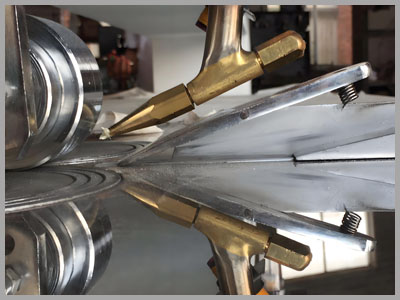

1. The heating pipe of sewing machine is made of imported heating wire. It is durable and melting glue thread is good.

2.The machine body is made of thick steel plate, which is strong stability. the worktable adopts 3mm thickness stainless steel plate

3. Using frequency conversion to control splicing speed 10-50m/min

WEIGHTED FUSELAGE

The machine structure is welded with thickened steel plate, and the body is painted to ensure the stability and service life of the machine

HIGH QUALITY HEATING WIRE

High quality heating wire: All copper core heating wire, high temperature resistance, by heating melting glue wire to combine the material. Make sure the splice is tight and secure

CONTROL PANEL

Touch screen control panel, simple and clear

OIL-WATER SEPARATOR

Oil-water separator: prevent water vapor from entering the cylinder, effectively extend the service life of pneumatic components

BRAND ELECTRICAL APPLIANCES

Brand electrical appliances: The electrical appliances are arranged neatly, and the electrical system of this machine is made of high quality electrical appliances at home and abroad

Our veneer splicing machine and plywood machine are exported to many countries like Malaysia,Indonesia, Russia, Turkey ,Brazil, Argentina, Paraguay and so on.

WIRELESS VERTICAL VENEER SPLICER

WIRELESS VERTICAL VENEER SPLICER

WIRELESS HORIZONTAL VENEER SPLICER

Spindleless peeler

Veneer dryer

Veneer composer

Hot press

Glue spreader

plywood trimming saw

Automatic putty line

Calibrating machine

Shandong kindle Machinery manufacture limited company

located in Linyi national Economic and Technological Deve-

lopment Zone, it was founded in 1998 which specialized in

research and development of veneer peeling machine for 26

years. It have obtained more than 60 national patents , it covers more than 30000㎡ area and have 15 R&D technician and 30 professional engineer for installation and machine maintaining.

![]()

We are committed to provide complete solutions for veneer

peeling line, plywood making plant,LVL,block board, PB,OSB production Line etc. Main equipment include: Log cutting saw, log debarker , spindle peeling lathe and spindleless wood veneer peeling machine,veneer dryer, glue spreader,pre-press, hot press, veneer commposer,plywood saw, sanding machine, boiler, and related plant accessories and materials, etc.

![]()

FAQ:

Q1:Are you machine manufacturer or a trading company?

A1: we are a factory which is special for producing veneer peeling machine and plywood machine,Jinduo company own 2 workshops and 1 trading company

Q2:What is the delivery time?

A2:In generally speaking , the complete veneer product line need about 30 days to manufacture after getting deposit.

Q3: what is the maintenance period and what kind of after sale service can you supply?

A3: the machinery part maintenance will be sustained in one year after installation and we have abroad warehouse and office for spare part in brazil and Russia, our engineer will arrive your factory to maintain the machine at first time if have problem.

Q4: what is the payment term?

A4: we can accept TT with 30% deposit and 70% balance against loading bill or 100% irrevocable L/C at sight.

Q5:can we visit your factory?

A6: Jinduo company is next to linyi airport, we can pick you up from airport to our factory at any time, welcome to visit us.