| Press plate size: | |

|---|---|

| Pressure: | |

| Weight: | |

| Layers: | |

| Availability: | |

JDRY48-500T

KINDLE

Place the prepared blanks steadily and accurately on the workbench of the hot press. Pay special attention to the accurate placement of the blanks, otherwise it will affect the pressing effect. After placement, close the press door, start the hot pressing program, and the equipment will enter the formal working state.

Machine parameter

| 1 | Model | BY21-4*8-600T-15 |

| 2 | Hot press plates size | 2700*1370*52 mm |

| 3 | Qunatity of hot press plates | 16 sheets, double inlet, double outlet |

| 4 | Quantity of layers | 15 layers |

| 5 | Hydraulic pistons | 4 units, diameter 280 mm |

| 6 | Pressure Capacity | 600 Tons |

| 7 | Opening size | 100 mm |

| 8 | Stroke of Cylinder | 1500 mm |

| 9 | No-load closing time | About 27 S |

| 10 | Hydraulic system control method | Automatic control and hand control |

| 11 | Hydraulic system limit pressure | 25 MPa |

| 12 | Low pressure pump and motors | 250 ml/rev 2 units, 11 KW motors 2 units |

| 13 | High pressure pump and motors | 10 ml/rev 1 unit , 5.5 KW motor 1 unit |

| 14 | Heating Meduim | heat transfer oils or steam |

| 15 | Top , Bottom , middle crossbeam | 1000 mm, 1000 mm, 400 mm |

| 16 | Frame structure | fixed with bolts, two gantry frames |

| 17 | Size of Main frame | 3560*1370*5500 mm |

| 18 | Main frame steel plate thickness | 30 mm , 12 mm |

| 19 | Gross Weight | 43,000 KG |

Excellent bonding strength:

The combination of scientific hot pressing technology and precise pressure, temperature and time control enables the plywood layers to be firmly bonded, and the bonding strength far exceeds that of products produced by ordinary hot presses, enhancing product durability.

WUXI CHROME CYLINDER

One of the best cylinder ensure high press and durable and have lifting cylinder to improve the close speed.

Chrome surface,anti-rust treatment,iron cast and heavy duty.

SOLID HOT PLATEN

Hot plate 4x8ft(Hot platen is optional)2700x1370x42mm or 2700x1370x52mm, Each platen has its own control valve.This ensure a easy maintenance in future.

Good thermal conductivity Keep smooth surface and tiny error, ensure your plywood smooth be good.

DURABLE SS SHEETS

These stainless - steel sheets enhance uniform heat transfer, preventing hotspots and ensuring every part of the workpiece is evenly processed. They also protect the hot press plates from corrosion, extending the machine's lifespan. Additionally, they contribute to a smoother finish on the processed materials, meeting the high - quality standards required in diverse industries.

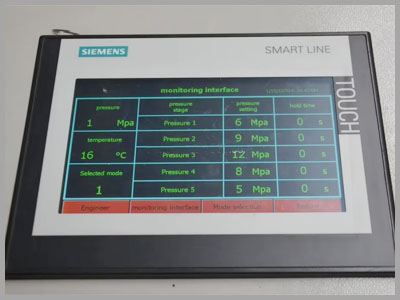

SIEMENS PLC CONTROL

SIEMENS PLC system,five different pressure control,six modes data for high quality plywood.

Adopt Taiwan Delta automatic PLC system,the whole machine is automatic operation,easy to operate.Electrical components aresiemens Brand.

HYDRAULIC SYSTEM

Hydraulic station,includes motor,oil pump and valve block etc.High quality from famous brands.

Hydraulic station uses TAlWAN hydrau-lic technology.lt uses Sicmens brandmotor,KINYUN solenoid valve,TAIWANHEANG bydraulic.

AUTOMATIC LOADING / UNLOADING DEVICE

1. Full automatic loader and unloader;good for 20-40 layers.

2. Semi automatic loader;good for 15-20 layers.

3. Manual feeding type,good for 10-15 layers.

We can also design hot press machine according to your requirements. So far, our company has successfully made 6*12ft size 2800Ton lamination hot press machine.

PLYWOOD FILMING HOT PRESS

PLYWOOD FILMING HOT PRESS

SHORT CYCLE MELAMINE PAPER FILMING PRESS

CURVED PRESS MACHINE

LATOFLEX ARC BENDING PRESS

DOOR BOARD PRESS MACHINE

AUTOMATIC COMPOSITE HOT PRESS MACHINE

Spindleless peeler

Card peeling machine

Veneer dryer

Veener peeling line

Cold press

plywood trimming saw

Automatic putty line

Glue spreader

Company Profile

Shandong kindle Machinery manufacture limited company located in Linyi national Economic and Technological Development Zone, it was founded in 1998 which specialized in research and development of veneer peeling machine for 26 years. It have obtained more than 60 national patents , it covers more than 30000 area and have 15 R&D technician and 30 professional engineer for installation and machine maintaining.

We are committed to provide complete solutions for veneer

peeling line, plywood making plant,LVL,block board, PB,OSB production Line etc. Main equipment include: Log cutting saw, log debarker , spindle peeling lathe and spindleless wood veneer peeling machine,veneer dryer, glue spreader,pre-press, hot press, veneer commposer,plywood saw, sanding machine, boiler, and related plant accessories and materials, etc.

FAQ:

Q1: Are you machine manufacturer or a trading company?

A1: We are a factory which is special for producing veneer peeling machine and plywood machine,Jinduo company own 2 workshops and 1 trading company.

Q2: What is the delivery time?

A2: In generally speaking , the complete veneer product line need about 30 days to manufacture after getting deposit.

Q3: What is the maintenance period and what kind of after sale service can you supply?

A3: The machinery part maintenance will be sustained in one year after installation and we have abroad warehouse and office for spare part in brazil and Russia, our engineer will arrive your factory to maintain the machine at first time if have problem.

Q4: What is the payment term?

A4: We can accept TT with 30% deposit and 70% balance against loading bill or 100% irrevocable L/C at sight.

Q5: Can we visit your factory?

A6: Jinduo company is next to linyi airport, we can pick you up from airport to our factory at any time, welcome to visit us.