| Feeding width: | |

|---|---|

| layers: | |

| hot press: | |

| product capacity: | |

| Availability: | |

JDHG48-15L

KINDLE

The 500t heavy-duty plywood cold press machine is a high-performance equipment designed for efficient and reliable plywood production. Boasting a robust 500-ton pressing capacity, it delivers uniform and powerful pressure across the entire plywood surface, ensuring strong and consistent bonding between layers without compromising material integrity. Equipped with advanced hydraulic systems and precise control panels, this machine allows for accurate adjustment of pressure, timing, and pressing speed, catering to various plywood thicknesses and material requirements. Its heavy-duty construction ensures durability and long-term stability even under continuous operation, making it ideal for large-scale industrial production.

Machine parameter

| Model | JDLY48-400T | JDLY48-500T |

| Nominal gross pressure | 400T | 500T |

| Nominal oil pressure | 25Mpa | 25Mpa |

| Number of cylinder | 2pcs | 2pcs |

| Place of cylinder | TOP | TOP |

| Size of hot press plate | 1370*2700MM | 1370*2700MM |

| Diameter of cylinder | 2*Ф320mm | 2*Ф360mm |

| Stroke of cylinder | 1050mm | 1050mm |

| Lifting cylinder | 2*Ф120mm | 2*Ф120mm |

| High pressure pump flow | 25M | 25M |

| Motor | 11kw | 11kw |

| Dimension | 3600*1370*4600mm | 3600*1370*4600mm |

| Opening | 1800mm | 1800mm |

| Total weight | 12500kgs | 13200kgs |

1. Most of the electrical components of this machine are chosen from Schneider or Chinese famous brands which are stable in operation.

2. The hydraulic cold press works with low noise, fast lifting speed, strong pressure stability and low maintenance rate.

3. Because the foreign voltage is different from our voltage, most of the domestic manufacturers only change the motor and don't care about the other electrical components, when customers use the cold press in the factory, the electrical components are easy to be heated and finally burned. And this will not happen to our cold press.

4. Equipped with automatic loading and unloading machine, it is convenient to convey and saves time and labor.

5. With over-pressure automatic control circuit and pressure oil cut-off protection, automatic lifting and oil cut-off.

6. Fast and efficient pressurization, emergency safety brake, stroke limit device. This machine is used for pre-pressing process of making plywood, also blockboard and decorative board.

CHINA BEST BRAND WUXI OIL CYLINDER

Equipped with wuxi solid cylinders which ensure the high pressure of the cold press machine and makes the machine more durable

HIGH DEGREE OF AUTOMATION

Equipped with automatic loading and unloading machine, it is convenient for conveying, saves time and labor, and has high working efficiency.

UPPER OIL CYLINDER

The pressure is more uniform, the overall structural stability of the equipment is high, and easy to maintain and overhaul, the arrangement of hydraulic piping is more concise and reasonable.

HYDRAULIC SYSTEM FOR COLD PRESS

Hydraulic station,includes motor,oil pump and valve block etc.High quality from famous brands. Hydraulic station uses TAlWAN hydrau-lic technology.lt uses Sicmens brandmotor KINYUN solenoid valve,TAIWANHEANG bydraulic

Our plywood cold pressing machine and plywood machine are exported to many countries like Malaysia,Indonesia, Russia, Turkey ,Brazil, Argentina, Paraguay and so on.

plywood packing cold press machine

Veneer packing cold press machine

Spindleless peeler

Veneer dryer

Veneer composer

Hot press

Glue spreader

Plywood trimming saw

Automatic putty line

Calibrating machine

Shandong kindle Machinery manufacture limited company

located in Linyi national Economic and Technological Deve-

lopment Zone, it was founded in 1998 which specialized in

research and development of veneer peeling machine for 26

years. It have obtained more than 60 national patents , it covers more than 30000㎡ area and have 15 R&D technician and 30 professional engineer for installation and machine maintaining.

![]()

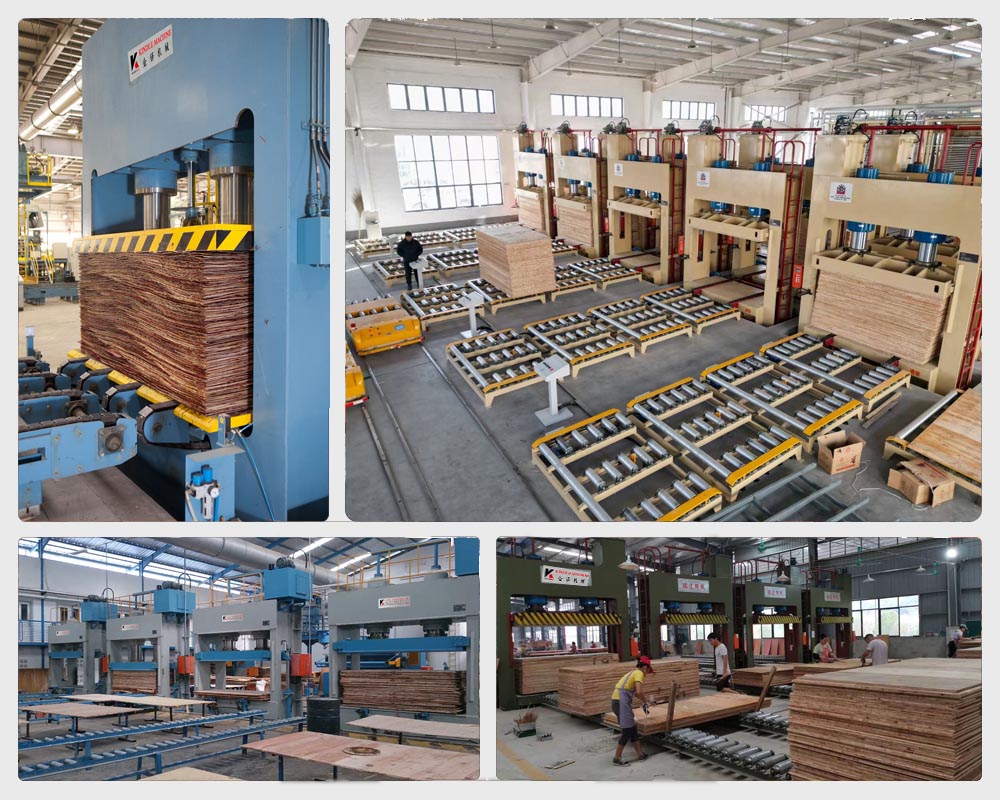

We are committed to provide complete solutions for veneer

peeling line, plywood making plant,LVL,block board, PB,OSB production Line etc. Main equipment include: Log cutting saw, log debarker , spindle peeling lathe and spindleless wood veneer peeling machine,veneer dryer, glue spreader,pre-press, hot press, veneer commposer,plywood saw, sanding machine, boiler, and related plant accessories and materials, etc.

![]()

FAQ:

Q1:Are you machine manufacturer or a trading company?

A1: we are a factory which is special for producing veneer peeling machine and plywood machine,Jinduo company own 2 workshops and 1 trading company

Q2:What is the delivery time?

A2:In generally speaking , the complete veneer product line need about 30 days to manufacture after getting deposit.

Q3: what is the maintenance period and what kind of after sale service can you supply?

A3: the machinery part maintenance will be sustained in one year after installation and we have abroad warehouse and office for spare part in brazil and Russia, our engineer will arrive your factory to maintain the machine at first time if have problem.

Q4: what is the payment term?

A4: we can accept TT with 30% deposit and 70% balance against loading bill or 100% irrevocable L/C at sight.

Q5:can we visit your factory?

A6: Jinduo company is next to linyi airport, we can pick you up from airport to our factory at any time, welcome to visit us.