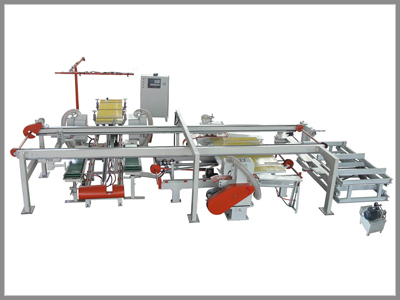

With its unique design, the glue coating machine adds color to plywood gluing.

| veneer width: | |

|---|---|

| rubber roller diameter: | |

| thickness adjustment: | |

| Availability: | |

JDTJ260-310

KINDLE

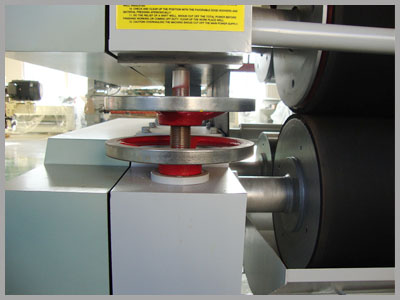

The top tightening force of the squeezing roller can be easily achieved by rotating the adjustment sleeve to change the spring pressure, ensuring that the squeezing force between the squeezing roller and the gluing roller is appropriate and controlling the glue application amount.

Machine parameter

| Model | JDTJ130P | JDTJ260P |

| Quantity of roller | 4 | 4 |

| Glue roller length | 1400mmm | 2700mm |

| Rubber roller diameter | 245mm/419mm | 245/419 mm |

| Thickness of rubber | 18 mm | 20 mm |

| Diameter of steel roller | 217 mm | 296mm |

| Hard cromed on surface of steel roller | YES | YES |

| Rotary speed of roller | 45 m/min/adjustable | 45 m/min/adjustable |

| Motor power | 3-4 kw | 7.5kw+7.5kw+1.5kw |

| Dimension | 2100*1250*1400mm | 3400*1350*1600mm |

| Weight | 1500kgs | 4600kgs |

1. The glue bucket of the equipment adopts a double-layer structure design, with an insulation layer in the middle, which can effectively keep the temperature of the glue liquid stable.

2. The glue roller of the glue coating machine is manufactured with high-precision processing technology, with high dimensional accuracy to ensure the uniformity of glue coating.

3. It has a drip-proof function, which can automatically stop the supply of glue after the glue coating is completed to prevent the glue from dripping on the single board and affecting the quality.

STEEL ROLLER

It is made of thickened seamless steel roller with uniform hard chromium plating, high hardness, rust prevention and even gluing

So smooth and notsticky which saves Glue and labor.

RUBBER ROLLER

Adopt 410mm diameter nitrile rubber, spreading speed is faster, can save more glue and the glue will be more average.

GEAR DRIVINGSYSTEM

Precise gear drive system,high quality and better working performance.All gears and drive components are phosphorization treated,resistant to corrosion

THICKNESS ADJUST HANDLE

For old type of glue spreader machine for plywood, total 5 hand wheel for locking and adjusting rubber roller opening.For new Z type of glue spreader machine,two hand wheels at front and two at back side.

Adjust the diatance between rollers, can spreading Glue on different thickness board, Easy to operate

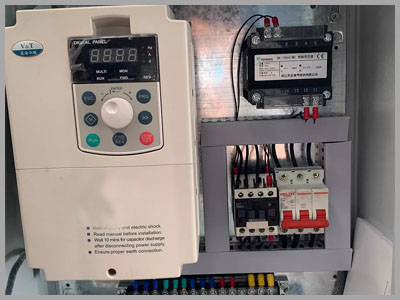

CONTROL SYSTEM

Operation system is controlled by the PLC system, which is much easier to operate. the front and rear jointing are synchronized that makes the veneer jointed very precisely in order to prevent overlapping

TRANSFER OUT CONVEYOR

This conveyor can be optional with standard model, it can transfer out the veneer smoothly, increase the product capacity and it's very convenient in the plywood product line, independent motor supply power to conveyor and the speed can be adjusted according to real product.

Our glue spreading machine and plywood machine are exported to many countries like Malaysia,Indonesia, Russia, Turkey ,Brazil, Argentina, Paraguay and so on.

Spindleless peeler

Card peeling machine

Veneer dryer

Hot press

Cold press

Veener composer

Automatic putty line

Edge cutting saw

Company Profile

Shandong kindle Machinery manufacture limited company located in Linyi national Economic and Technological Development Zone, it was founded in 1998 which specialized in research and development of veneer peeling machine for 26 years. It have obtained more than 60 national patents , it covers more than 30000 area and have 15 R&D technician and 30 professional engineer for installation and machine maintaining.

We are committed to provide complete solutions for veneer

peeling line, plywood making plant,LVL,block board, PB,OSB production Line etc. Main equipment include: Log cutting saw, log debarker , spindle peeling lathe and spindleless wood veneer peeling machine,veneer dryer, glue spreader,pre-press, hot press, veneer commposer,plywood saw, sanding machine, boiler, and related plant accessories and materials, etc.

FAQ:

Q1: Are you machine manufacturer or a trading company?

A1: We are a factory which is special for producing veneer peeling machine and plywood machine,Jinduo company own 2 workshops and 1 trading company.

Q2: What is the delivery time?

A2: In generally speaking , the complete veneer product line need about 30 days to manufacture after getting deposit.

Q3: What is the maintenance period and what kind of after sale service can you supply?

A3: The machinery part maintenance will be sustained in one year after installation and we have abroad warehouse and office for spare part in brazil and Russia, our engineer will arrive your factory to maintain the machine at first time if have problem.

Q4: What is the payment term?

A4: We can accept TT with 30% deposit and 70% balance against loading bill or 100% irrevocable L/C at sight.

Q5: Can we visit your factory?

A6: Jinduo company is next to linyi airport, we can pick you up from airport to our factory at any time, welcome to visit us.