| veneer width: | |

|---|---|

| rubber roller diameter: | |

| thickness adjustment: | |

| Availability: | |

JDTJ260-310

KINDLE

The heavy duty veneer coating machine is engineered for reliable performance in plywood production, designed to handle demanding industrial workflows with ease. Built with robust materials, it ensures consistent and uniform glue application across veneer surfaces, enhancing bonding strength and reducing material waste. The machine integrates user-friendly controls for seamless operation, adapting to various veneer thicknesses and types to meet diverse production needs. Its heavy duty construction guarantees long term durability, minimizing downtime and maintaining high productivity in busy manufacturing environments. Ideal for plywood manufacturers seeking precision, efficiency, and durability, this coating machine streamlines the gluing process, contributing to smoother production cycles and superior end-product quality.

Machine parameter

| Model | JDTJ130P | JDTJ260P |

| Quantity of roller | 4 | 4 |

| Glue roller length | 1400mmm | 2700mm |

| Rubber roller diameter | 410mm | 419 mm |

| Thickness of rubber | 18 mm | 20 mm |

| Diameter of steel roller | 275mm | 297mm |

| Hard cromed on surface of steel roller | YES | YES |

| Rotary speed of roller | 45 m/min/adjustable | 45 m/min/adjustable |

| Motor power | 3-4 kw | 7.5kw+7.5kw+1.5kw |

| Dimension | 3550*1250*1400mm | 4200*1350*1600mm |

| Weight | 3500kgs | 5200kgs |

Engineered with robust construction, the heavy duty plywood coating machine withstands rigorous industrial use, ensuring long-term reliability and minimal maintenance needs.

It delivers precise, uniform adhesive application across plywood surfaces, enhancing bonding strength and reducing material waste for consistent quality outputs.

Equipped with user-friendly controls, it simplifies operation and minimizes training time, boosting workflow efficiency in busy manufacturing environments.

Its heavy-duty design supports continuous high-volume production, reducing downtime and maximizing productivity for plywood manufacturers.

STEEL ROLLER

The metal rollers spread glue evenly, so every part of the veneer gets just the right amount—no wasted glue, and stronger bonds.

RUBBER ROLLER

Adopt 410mm diameter nitrile rubber, spreading speed is faster, can save more glue and the glue will be more average.

GEAR DRIVINGSYSTEM

Precise gear drive system,high quality and better working performance.All gears and drive components are phosphorization treated,resistant to corrosion

PNEUMATIC DRIVE SYSTEM

Uses compressed air to control glue application pressure, ensuring stable, adjustable force for consistent coating across veneers, even with varying material textures.

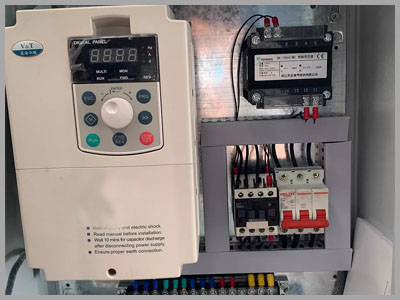

CONTROL SYSTEM

The control panel of the glue spreader is designed with simplicity in mind. It features easy - to - use knobs and switches for adjusting the speed, glue flow rate, and other parameters. Even operators with limited technical knowledge can quickly master the operation. Additionally, the control panel is equipped with clear indicators for power, operation status, and any potential error messages, enabling timely troubleshooting.

ROBUST FRAME STRUCTURE

This robust construction ensures the machine can withstand the rigors of continuous operation in a plywood production environment. It provides a stable base for all internal components, guaranteeing smooth operation and preventing vibrations that could affect the quality of glue application.

Our glue spreading machine and plywood machine are exported to many countries like Malaysia,Indonesia, Russia, Turkey ,Brazil, Argentina, Paraguay and so on.

Spindleless peeler

Veneer dryer

Veneer composer

Hot press

Veneer composer

Plywood trimming saw

Automatic putty line

Calibrating machine

KINDLE COMPANY

Shandong kindle Machinery manufacture limited company

located in Linyi national Economic and Technological Deve-

lopment Zone, it was founded in 1998 which specialized in

research and development of veneer peeling machine for 26

years. It have obtained more than 60 national patents , it covers more than 30000㎡ area and have 15 R&D technician and 30 professional engineer for installation and machine maintaining.

![]()

We are committed to provide complete solutions for veneer

peeling line, plywood making plant,LVL,block board, PB,OSB production Line etc. Main equipment include: Log cutting saw, log debarker , spindle peeling lathe and spindleless wood veneer peeling machine,veneer dryer, glue spreader,pre-press, hot press, veneer commposer,plywood saw, sanding machine, boiler, and related plant accessories and materials, etc.

![]()

FAQ:

Q1:Are you machine manufacturer or a trading company?

A1: we are a factory which is special for producing veneer peeling machine and plywood machine,Jinduo company own 2 workshops and 1 trading company

Q2:What is the delivery time?

A2:In generally speaking , the complete veneer product line need about 30 days to manufacture after getting deposit.

Q3: what is the maintenance period and what kind of after sale service can you supply?

A3: the machinery part maintenance will be sustained in one year after installation and we have abroad warehouse and office for spare part in brazil and Russia, our engineer will arrive your factory to maintain the machine at first time if have problem.

Q4: what is the payment term?

A4: we can accept TT with 30% deposit and 70% balance against loading bill or 100% irrevocable L/C at sight.

Q5:can we visit your factory?

A6: Jinduo company is next to linyi airport, we can pick you up from airport to our factory at any time, welcome to visit us.