| blade size : | |

|---|---|

| veneer thickness: | |

| cutting width: | |

| Availability: | |

SKZ130-40A

kindle

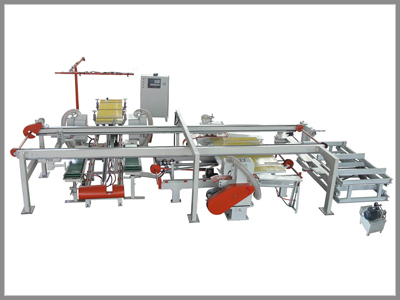

Core / face veneer clipper

Veneer clipping Machine is a kind of machine designed for cutting the veneers which has been peeled from veneer peeling lathe.The blade is fixed on a light alloy knife holder, and cuts the veneer against the supporting drum.It will take about 1/20 second for one stroke.

MACHINE PARAMETER:

Model | JQZ1500 | JQZ2700 | JQZ3300 |

Max working width | 1500mm | 2700mm | 3300mm |

Knife quantity | 1-3 pcs | 1-3 pcs | 1-3 pcs |

Cutting power | 5.5kw | 7.5kw | 11kw |

Transport power | 4kw | 5.5kw | 7.5kw |

cutting speed | 0-100m/min(adjustable) | 0-100m/min(adjustable) | 0-100m/min(adjustable) |

Max feeding speed | 100m/min | 100m/min | 100m/min |

Veneer thickness | 0.3-4.0mm | 0.3-4.0mm | 0.3-4.0m |

| Cutting method | machinery / pneumatic | machinery / pneumatic | machinery / pneumatic |

Weight | 2200kgs | 3300kgs | 3800kgs |

Overall size | 6000x2684x1740mm | 6000x3860x1740mm | 6700X3860X1740MM |

The Veneer Clipper connects with a wood veneer peeling machine for automatic cutting of veneers to the required width. Its working speed matches your veneer rotary lathe. Our veneer clipper is made from high-quality materials, making it very heavy, which ensure stability and a long lifespan. It is also equipped with the reliable eletrical box and high-quality components. We can customize the veneer clipper or veneer guillotine according to your specific veneer dimensions, providing tailored solutions to meet your production needs.

BIG DIAMETER RUBBER ROLLER

The roller rubber diameter is about 250mm, much bigger than normal type, increase the working life and don't need change the roller often, the material adopt hard rubber, not easy to wear, helpful to increase the working time.

THREE BLADES FOR NARROW VENEER

The quantity of blades is decided by the minimum veneer width, if the first veneer need to be cut in small pieces, then the blades can be installed three pieces, the range of cutting veneer is widely.

ENCODER FOR CONTROL

The hige precision encoder is used to collect the size of veneer and feedback to control system, so the speed can be adjusted according to the signal, in this way, can build a closed control circle, so can promise the veneer cutting precision is high.

AUTOMATIC CONTORL UNIT

CNC control, fully automatical design, knife shaft and veneer conveyor adopt servo system, automatic trimming of veneer, highworking efficiency. Cutting speed can be 100m/min

We can also design the wood veneer clipper according to your requirements. So far, our company has successfully made 2 feet, 4 feet, 8 feet, 10 feet, 12 feed veneer rotary cutting machine for log peeling lathe.

MECHANICAL VENEER CUTTING MACHINE

MECHANICAL VENEER CUTTING MACHINE

VENEER GUILLOTING MACHINE

FACE VENEER SCISSORS

MANUAL VENEER CUTTER

VENEER PEELING LINE

VENEER DRYER

GLUE SPREADER

VENEER COMPOSER

PLYWOOD PUTTY LINE

PLYWOOD CUTTING SAW

CALIBRATING MACHINE

KNIFE GRINDER

Shandong kindle Machinery manufacture limited company

located in Linyi national Economic and Technological Deve-

lopment Zone, it was founded in 1998 which specialized in

research and development of veneer peeling machine for 26

years. It have obtained more than 60 national patents , it covers more than 30000㎡ area and have 15 R&D technician and 30 professional engineer for installation and machine maintaining.

We are committed to provide complete solutions for veneer

peeling line, plywood making plant,LVL,block board, PB,OSB production Line etc. Main equipment include: Log cutting saw, log debarker , spindle peeling lathe and spindleless wood veneer peeling machine,veneer dryer, glue spreader,pre-press, hot press, veneer commposer,plywood saw, sanding machine, boiler, and related plant accessories and materials, etc.

Q1:Are you machine manufacturer or a trading company?

A1: we are a factory which is special for producing veneer peeling machine and plywood machine,Jinduo company own 2 workshops and 1 trading company

Q2:What is the delivery time?

A2:In generally speaking , the complete veneer product line need about 30 days to manufacture after getting deposit.

Q3: what is the maintenance period and what kind of after sale service can you supply?

A3: the machinery part maintenance will be sustained in one year after installation and we have abroad warehouse and office for spare part in brazil and Russia, our engineer will arrive your factory to maintain the machine at first time if have problem.

Q4: what is the payment term?

A4: we can accept TT with 30% deposit and 70% balance against loading bill or 100% irrevocable L/C at sight.

Q5:can we visit your factory?

A6: Jinduo company is next to linyi airport, we can pick you up from airport to our factory at any time, welcome to visit us.