| Weight: | |

|---|---|

| Rated Steam Pressure: | |

| Rated Evaporation : | |

| Availability: | |

XQLSX260-50A

KINDLE

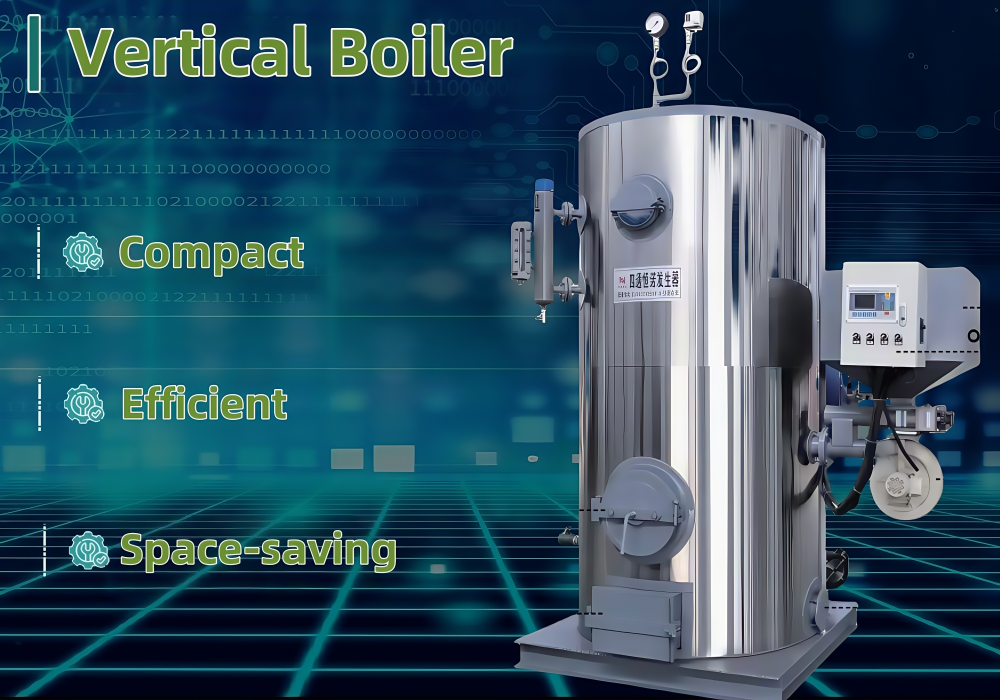

A vertical boiler is a steam/hot water boiler with a vertical design. Its core features include a small footprint and flexible installation, making it particularly suitable for space-constrained industrial environments such as plywood plants and small wood processing plants. The boiler is cylindrical and arranged vertically, with the combustion chamber at the bottom and smoke pipes or water pipes arranged vertically. Its thermal efficiency typically reaches 85%-90%. In plywood production, it is primarily used to provide stable steam for the hot press and heat energy required for veneer drying.

Machine parameter

| Product name | Biomass steam generator | |||

| Rated stea Rat Rated steam pressure(MPa) | 0.09/0.7 | |||

| Rated steam temperature(℃) | 118 | |||

| Feed water temperature(℃) | 20 | |||

| Thermal efficiency(%) | 83 | |||

| Supply voltage(V) | 220/380 | |||

| Color | Customers Requirment | |||

| Thermal efficiency | 96% | |||

1. Compact vertical structure, saving plant space: the floor space is 40%-50% less than that of horizontal boilers, which is particularly suitable for the working conditions of plywood plants with limited space. The vertical design reduces the complexity of steam pipelines and reduces the loss of heat energy transmission.

2. Efficient biomass combustion, reducing fuel costs: the patented stepped grate design is compatible with wood waste such as bark and sawdust, and has high combustion efficiency.

3. Quick response to plywood process requirements: the rated steam pressure can be reached within 5 minutes to meet the instantaneous steam demand of the hot press.

Three coil pipes

The innovative three-coil-pipe configuration significantly increases the boiler's heating surface area compared to traditional designs. This expanded contact area allows for more efficient heat transfer from combustion gases to the water, maximizing thermal efficiency and reducing fuel consumption.

Waste fuel conversion

Revolutionizing Combustion Efficiency with Advanced Vortex Technology. Vortex-Enhanced Burning: Creates intense swirling airflow to ensure 99.9% fuel burnout rate. Thermal Efficiency Boost: Increases overall boiler efficiency by 12-18%.

One-piece welded pipe bending

This technology significantly improves production efficiency and ensures structural strength by completing both welding and bending in one process. It avoids the errors and material loss associated with traditional segmented processing, resulting in improved heat transfer efficiency and a longer service life for boiler piping systems, while also reducing production costs and maintenance requirements.

Our boilers are exported to many countries like Malaysia,Indonesia, Russia, Turkey ,Brazil, Argentina, Paraguay and so on.

Spindle peeling machine

Veneer dryer

Veneer composer

Hot press

Glue spreader

plywood trimming saw

Automatic putty line

Calibrating machine

KINDLE COMPANY

Shandong kindle Machinery manufacture limited company

located in Linyi national Economic and Technological Deve-

lopment Zone, it was founded in 1998 which specialized in

research and development of veneer peeling machine for 26

years. It have obtained more than 60 national patents , it covers more than 30000 area and have 15 R&D technician and 30 professional engineer for installation and machine maintaining.

![]()

We are committed to provide complete solutions for veneer

peeling line, plywood making plant,LVL,block board, PB,OSB production Line etc. Main equipment include: Log cutting saw, log debarker , spindle peeling lathe and spindleless wood veneer peeling machine,veneer dryer, glue spreader,pre-press, hot press, veneer commposer,plywood saw, sanding machine, boiler, and related plant accessories and materials, etc.

![]()

FAQ:

Q1: Are you machine manufacturer or a trading company?

A1: We are a factory which is special for producing veneer peeling machine and plywood machine,Jinduo company own 2 workshops and 1 trading company.

Q2: What is the delivery time?

A2: In generally speaking , the complete veneer product line need about 30 days to manufacture after getting deposit.

Q3: How quickly can you get the best price?

A3: (1) We need to know the capacity of the boiler, the fuel you plan to use and your steam pressure needs, then we can confirm the model.

(2) Customers need to provide us with your name, email address and company name, then we will send you the price list immediately. Moreover, if you use whatsapp, skype or wechat, then you can provide us your ID, which will be more convenient for us to communicate.

Q4: Why choose us?

A4: (1)Class A boiler production qualification factory with many years export experience;

(2)100% steel plate, steel pipe, welding rod without damage;

(3)100% x-ray inspection (welds): ensure the quality of the whole boiler;

(4) Water pressure test: to ensure standard working pressure and safety;

Q5: What is the service life of your boiler?

A5: Usually with proper operation and good maintenance, the boiler can last for more than 20 years.