Adhesive curing time can be monitored during the manual panel process for optimal bonding performance.

| Working Table: | |

|---|---|

| Weight: | |

| Total Power: | |

| Availability: | |

KINDLE

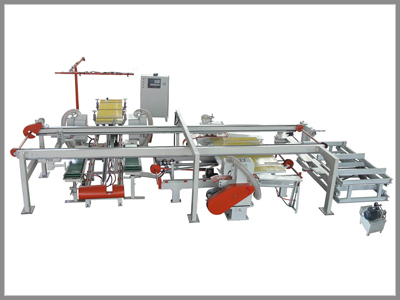

VEENER PAVING LINE

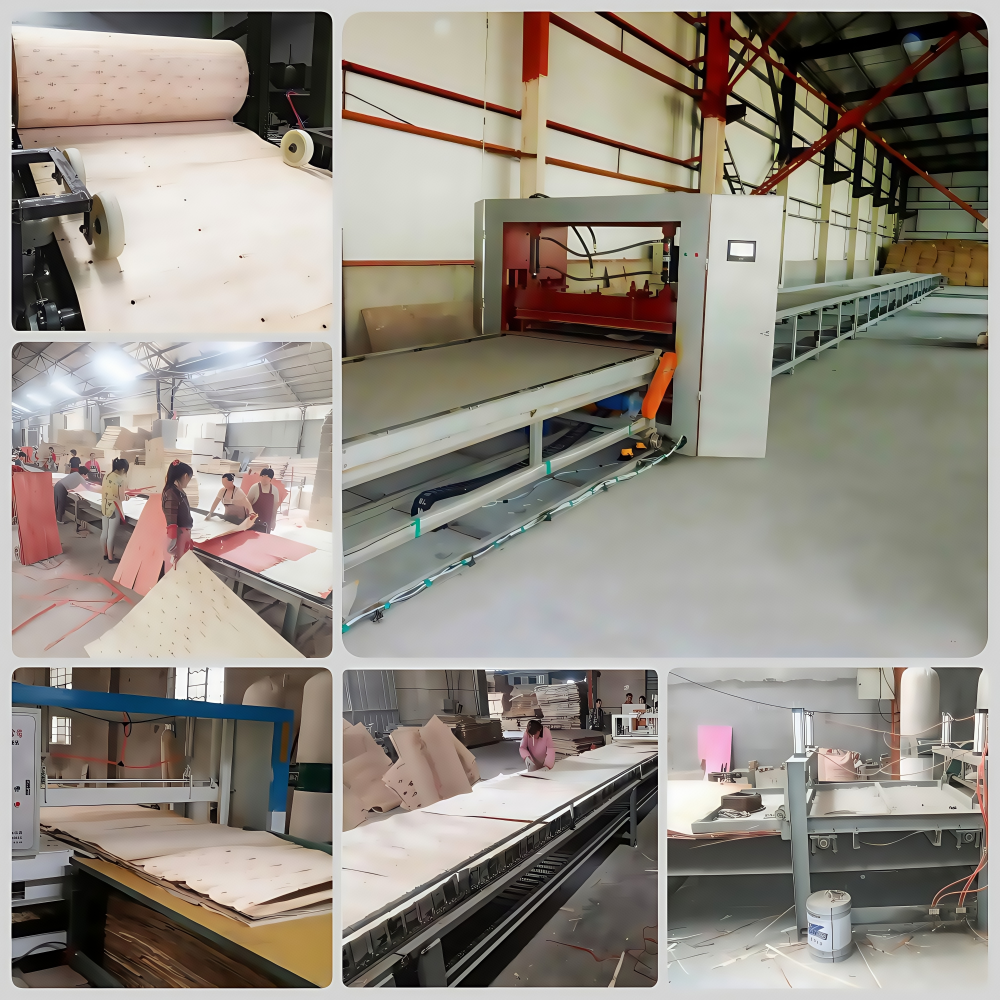

There is a reduced risk of damage to delicate veneers. Workers can handle these materials with care, ensuring the integrity of the final product. Workers on manual lines can improvise solutions during production. They can quickly address unforeseen challenges, maintaining the flow of production without waiting for technical support.

Machine parameter

| Model | HB-PZ0012 |

| Working board size | 1220*2440mm |

| Lay-up head size | 3000*1580*1150mm |

| Working table | 25m |

| Conveyor speed | 5-10m/min |

| The cutting way | SaW |

| Loading style | vertical down |

| Control type | PLC control |

| Total power | 13.5kw |

| Weight | About 5 Ton |

1. Good appearance: The overall appearance of the plywood laying line is beautiful and generous. The surface is sprayed and treated, which is not only corrosion - resistant and wear - resistant but also enhances the overall image of the workshop.

2. Data recording function: It can record production data such as the number of plywood laid and the working time, which is convenient for production management and quality tracking.

3. Automatic detection: It is equipped with sensors to automatically detect the quality and size of the plywood, and can alarm and stop the machine in case of problems to ensure the quality of the product.

High Accuracy

Normally one worker is in charge of one layer. In order to ensure thesmooth progress of the whole process, each work must be carriedout efficiently.

Save Material

Compared with theordinary paving table, it can save a lot of core plates when cutting parts, and canbe assembled continuously in thewhole working process.

Employee Management

lt is easy to check the work performance and efficiency of each employee to help manage employees.

Our paving line are exported to many countries like Malaysia,Indonesia, Russia, Turkey ,Brazil, Argentina, Paraguay and so on.

Spindleless peeler

Card peeling machine

Veneer dryer

Hot press

Cold press

Veener composer

Sanding machine

Edge cutting saw

Company Profile

Shandong kindle Machinery manufacture limited company located in Linyi national Economic and Technological Development Zone, it was founded in 1998 which specialized in research and development of veneer peeling machine for 26 years. It have obtained more than 60 national patents , it covers more than 30000 area and have 15 R&D technician and 30 professional engineer for installation and machine maintaining.

We are committed to provide complete solutions for veneer

peeling line, plywood making plant,LVL,block board, PB,OSB production Line etc. Main equipment include: Log cutting saw, log debarker , spindle peeling lathe and spindleless wood veneer peeling machine,veneer dryer, glue spreader,pre-press, hot press, veneer commposer,plywood saw, sanding machine, boiler, and related plant accessories and materials, etc.

FAQ:

Q1: Are you machine manufacturer or a trading company?

A1: We are a factory which is special for producing veneer peeling machine and plywood machine,Jinduo company own 2 workshops and 1 trading company.

Q2: What is the delivery time?

A2: In generally speaking , the complete veneer product line need about 30 days to manufacture after getting deposit.

Q3: What is the maintenance period and what kind of after sale service can you supply?

A3: The machinery part maintenance will be sustained in one year after installation and we have abroad warehouse and office for spare part in brazil and Russia, our engineer will arrive your factory to maintain the machine at first time if have problem.

Q4: What is the payment term?

A4: We can accept TT with 30% deposit and 70% balance against loading bill or 100% irrevocable L/C at sight.

Q5: Can we visit your factory?

A6: Jinduo company is next to linyi airport, we can pick you up from airport to our factory at any time, welcome to visit us.