| Work stroke: | |

|---|---|

| Saw blade parameters: | |

| Weight: | |

| Availability: | |

KDC-120

KINDLE

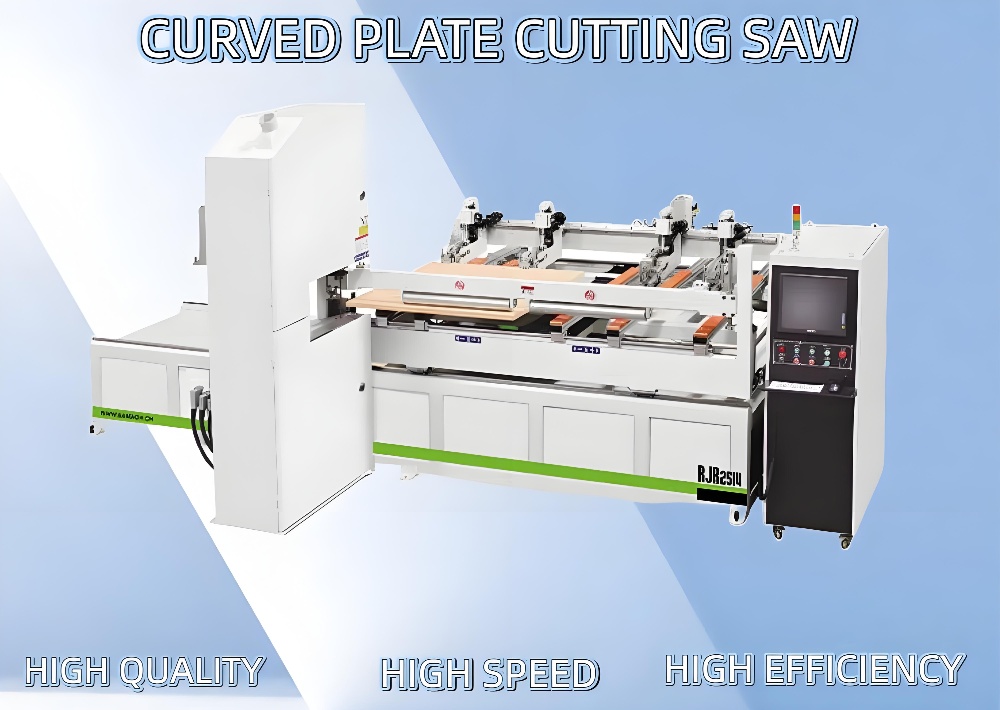

The Full Automatic CNC Curved Plate Cutting Saw is an advanced industrial tool designed for precision cutting of curved plates. Powered by sophisticated CNC technology, it enables fully automated operation, minimizing manual intervention and ensuring consistent results across batches. Its intelligent system adapts to various curved profiles, handling different materials with ease while delivering smooth, accurate cuts that meet strict quality standards. Equipped with user-friendly controls, operators can easily program cutting parameters, adjusting to specific project requirements without complex setups. The machine’s robust construction supports continuous operation, enhancing workflow efficiency and reducing downtime. Ideal for industries requiring customized curved plate processing, it combines automation, precision, and reliability to streamline production and elevate product quality.

Machine parameter

| Model | GY1500-T |

| Work stroke | 1200*1400*180mm |

| Saw wheel diameter | 760*60mm |

| Saw blade parameters | 5340*13*0.9mm |

| Saw blade rotation angle | -90°~+90° |

| Work speed | 1-15m/min |

| Return speed | 60m/min |

| Size | 3500*2300*2600mm |

| Weight | 2800kgs |

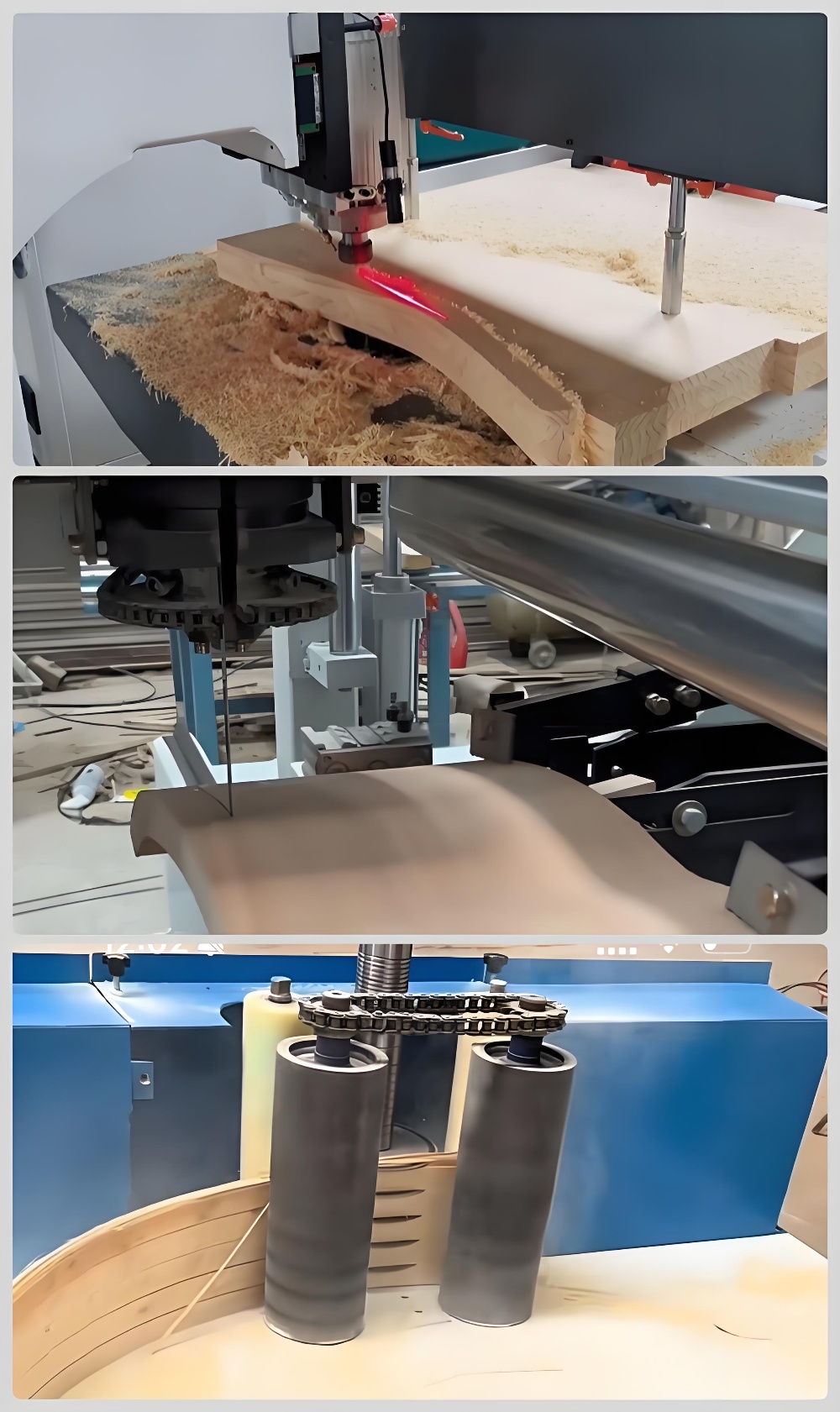

1.The linear guide way and precision screw ensures smooth and accurate sizing.

2.Center Saw Wheel Design ensures saw wheel running stabilize and extend the working life of the saw wheel. Also reduce the probability of the blades break down.

3.Hydraulic motor up and down the saw head.

4.Wear-resisting saw wheel pass the dynamic balancing emendation ensures running smoothly.

5.Clutch to protect the engine and easy to change blades.

6.Sweden SKF Bearings ensures the quality of the sawmill.

SAW DISK CLEANING DEVICE

This device efficiently removes debris, resin, and sawdust from saw disks during or after operation. It prevents buildup that could hinder cutting precision, reduces blade wear, and maintains consistent performance, extending tool lifespan and ensuring safer, smoother workflows.

COMPUTER CONTROL SYSTEM

It processes data, adjusts parameters in real-time, and coordinates mechanical parts for precise, efficient work. User-friendly interfaces simplify setup, enhancing control accuracy and reducing manual errors.

SAW BLADE ROTATION OF ±90°

Saw blade rotation of ±90 degrees enables flexible cutting in multiple directions. It allows quick switching between horizontal and vertical cuts, adapting to diverse workpiece angles and shapes, enhancing operational versatility for varied processing needs.

ABRASION-RESISTANT ELECTRIC WOOD BOARD

Abrasion-resistant electric wood board combines durability and functionality. Its surface resists wear from friction, ensuring long-term use without easy scuffing or damage. Suitable for high-traffic areas or frequent contact scenarios, it maintains a neat appearance while offering reliable performance in various woodworking or interior applications.

Our log cutting saw,log debarker and automatic veneer peeling line are exported to many countries like Malaysia,Indonesia, Russia, Turkey ,Brazil, Argentina, Paraguay and so on.

Veneer peeling line

Veneer dryer

Veneer composer

Hot press

Glue spreader

plywood trimming saw

Automatic putty line

Calibrating machine

Shandong kindle Machinery manufacture limited company

located in Linyi national Economic and Technological Deve-

lopment Zone, it was founded in 1998 which specialized in

research and development of veneer peeling machine for 26

years. It have obtained more than 60 national patents , it covers more than 30000㎡ area and have 15 R&D technician and 30 professional engineer for installation and machine maintaining.

![]()

We are committed to provide complete solutions for veneer

peeling line, plywood making plant,LVL,block board, PB,OSB production Line etc. Main equipment include: Log cutting saw, log debarker , spindle peeling lathe and spindleless wood veneer peeling machine,veneer dryer, glue spreader,pre-press, hot press, veneer commposer,plywood saw, sanding machine, boiler, and related plant accessories and materials, etc.

![]()

Q1:Are you machine manufacturer or a trading company?

A1: we are a factory which is special for producing veneer peeling machine and plywood machine,Jinduo company own 2 workshops and 1 trading company

Q2:What is the delivery time?

A2:In generally speaking , the complete veneer product line need about 30 days to manufacture after getting deposit.

Q3: what is the maintenance period and what kind of after sale service can you supply?

A3: the machinery part maintenance will be sustained in one year after installation and we have abroad warehouse and office for spare part in brazil and Russia, our engineer will arrive your factory to maintain the machine at first time if have problem.

Q4: what is the payment term?

A4: we can accept TT with 30% deposit and 70% balance against loading bill or 100% irrevocable L/C at sight.

Q5:can we visit your factory?

A6: Jinduo company is next to linyi airport, we can pick you up from airport to our factory at any time, welcome to visit us.